WORKHOLDING:

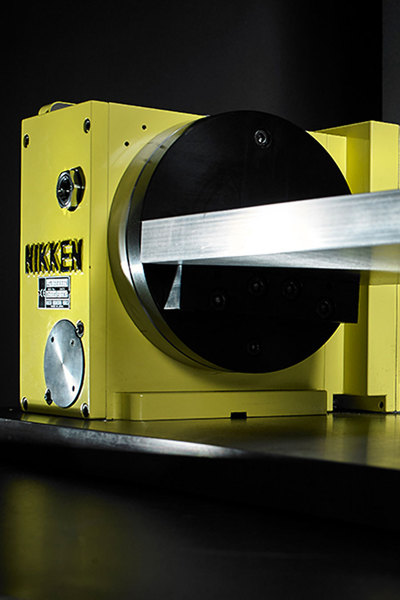

Whether you have already installed additional axes for your machine tool or are considering the benefits of such an investment to increase the productivity and scope of your platform, NIKKEN has a Work Holding solution to meet any requirement.

NIKKEN offer a complete range of work holding and fixturing accessories to suit any application. Whether it’s a standard, off-the-shelf centring vice or a fully bespoke fixturing package, our team of skilled engineers are available to create a package to suit your process for either direct supply or as part of a full turn-key solution.

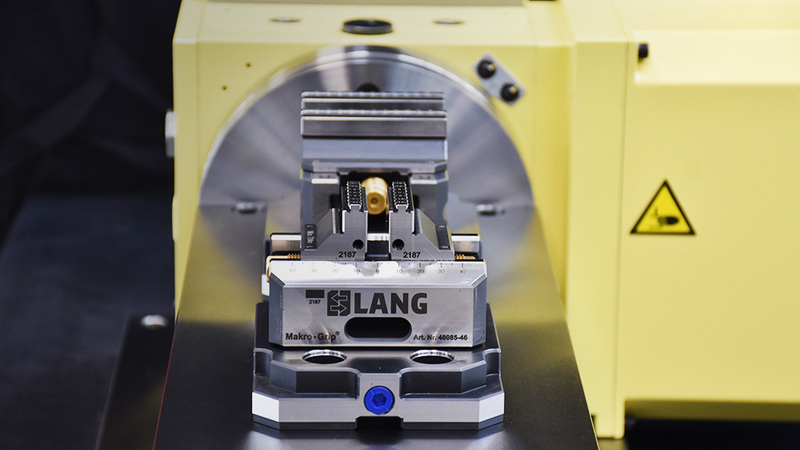

Popular setups include but are not limited to; vices (with various jaw options), tombstones, pallets, trunnion setups and rail systems, all fully zero-point compatible to ensure optimal efficiency, accuracy and repeatability, in addition to being available to view at our Innovation Centre.

Both our own and our partner-manufactured accessories and equipment are available on a fast turnaround.

Sustainability Advantages With NIKKEN Workholding:

Sustainability advantages that can be experienced and employed on any machine tool, in conjunction with the integration of a NIKKEN rotary table, are our workholding solutions. These can instantly increase any platform's productivity and lower manufacturing costs.

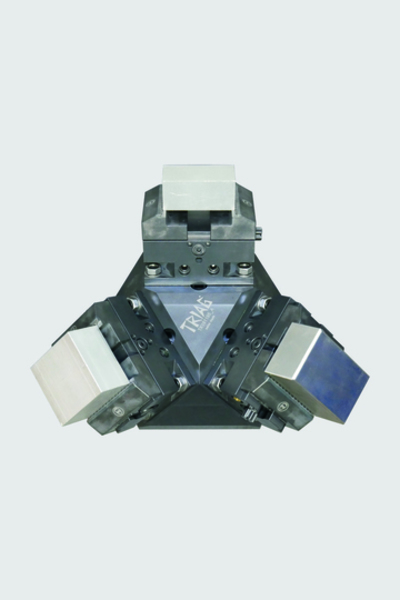

- With the addition of one of our market-leading two-sided trunnion assemblies or tombstones, the machine tool and NIKKEN rotary table are instantly capable of multi-sided machining.

- The process is reduced to only two operations, with three sides achieved on the trunnion's top face and the other three sides completed on the lower face.