NIKKEN I/O

NIKKEN are leading the way by utilising the latest, cloud-based technology to access big data during the lifetime of our products.

Providing you with full Industry 4.0 compliance, we’ve created a new passive, continuous, condition monitoring system (NIKKEN I/O) that runs day in, day out to ensure that you are kept up-to-date on the running of your NIKKEN products. Being able to sense and predict failure is a major asset to both the end-user – in maintaining uptime of machines, and to NIKKEN itself – to research and develop our products for the future.

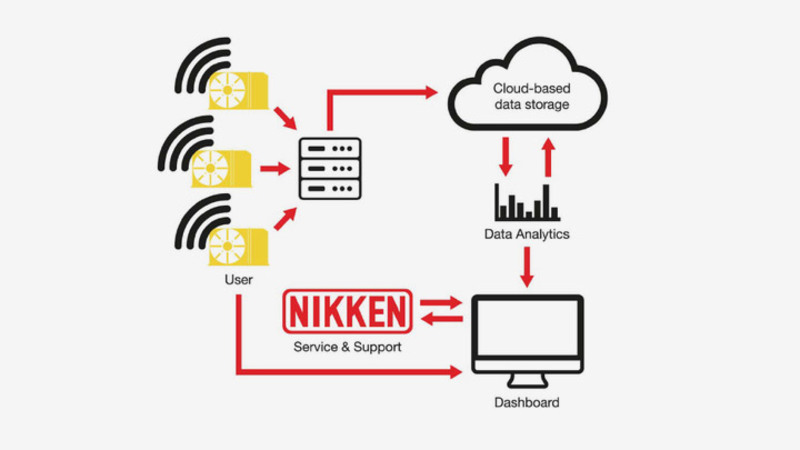

HOW I/O WORKS

- Sensors inside the rotary table send real-time data wirelessly while in production.

- A receiver on the workshop floor receives this data, performs the required processing, and enters it into a database.

- NIKKEN I/O uses a standalone web-based dashboard, providing rich, customisable data visuals with an at a glance flagging system, so you can see the beginning of an issue before it becomes a fault.

- Running over wi-fi, NIKKEN I/O can be connected to any local network, or even as a global cloud-based solution.

Servicing Standard

Servicing Base Plugin as standard:

- Backlash measurement

- Collision detection

- Oil condition monitoring

- Current measurement shows actual power draw of rotary during production

- Measurement of motor temperature gives indication of overheating.

Additional Options

Dynamics Plugin:

Vibration monitoring provides frequency information to aid operators in reducing vibration uniquely on the rotary workpiece.

Digital Signature Plugin:

NIKKEN I/O Servicing system data is opened to user. Bespoke system can identify process issues before inspection – reducing scrap and rework.