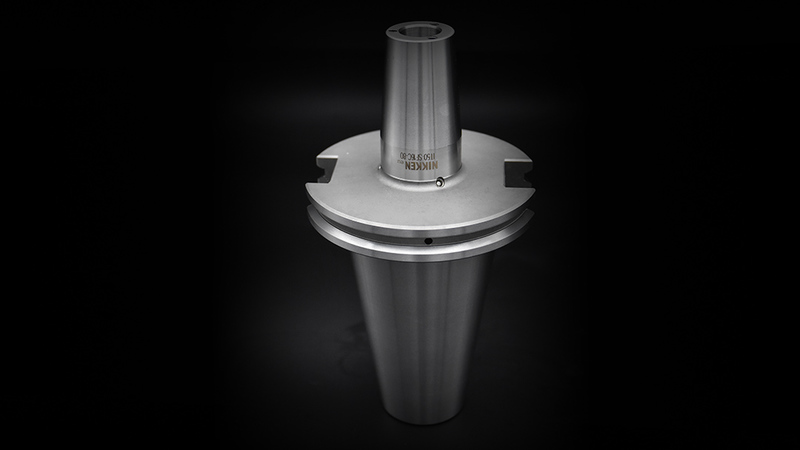

Under our new exclusive brand for Europe, NIKKEN eu, we are delighted to launch the ultimate Shrink-Fit solution. Developed and manufactured using carefully selected materials and processes, our latest tool holding range has been designed to meet the demands of any application requirement, in the most competitive markets.

Sourced from our own NIKKEN certified European manufacturer, allowing for more ‘local’ production and minimal logistics costs, the range will maintain and deliver NIKKEN’s renowned quality and support, while providing a more cost-effective solution for those considering ‘price per pot’ and budget constraints.

The range is produced using the latest machine tool and inspection technology and, like NIKKEN’s own solutions, is finally 100% ground to deliver a premium final solution. Available from stock to suit the majority of machine tool shank requirements (NIKKEN NBT, HSK, DIN69871/IT and Polygon tapers) our new Shrink-Fit tooling should suit numerous applications and processes.

-

Precise Toolholder Balancing

Ensuring a better surface finish

-

Superior Tool Runout

Runout of less than 0,003 mm

-

Greater Rigidity

Tool shank is gripped at 360 degrees for the whole bore length

-

Increased Tool Life

Better distribution of chip load along the cutting edge

-

Internal Coolant Supply

Allowing for coolant through the tool or around the tool

-

Easy Operation

Designed for a quick tool change

One key feature of the range is our unique internal design. The main bore is manufactured with a slightly increased front recess diameter which effectively minimises the amount of heat required for the shrinking process. This configuration also provides easy tool loading, reduces the of tool holder damage whilst also ensuring longer life and reliability.

NIKKEN EU also supplies, from stock, various options for coolant control to meet the individual requirements of the respective cutting tool. One such capability is the possibility to select our solutions with three ‘Jet’ holes which can be sealed using grub screws. This allows the user to either cool through the tool or around the tool making it the ideal choice to cater for the specifics of the tool, application and process.

NIKKEN are delighted to be able to offer a full range of third party manufactured THERMOGRIP® Shrink-Fit machines.

These solutions are our preferred choice with features and capabilities that complement some of the design elements ‘built-in’ to our new range of NIKKEN eu Shrink-Fit tool holders.

Our recommended solution is the ISG3400WK professional series which provides fully automatic shrinking and cooling for straight forward non-contact loading and removal of the cutting tool.

NIKKEN eu Shrink-Fit Toolholding

(PDF - 2.96 MB)