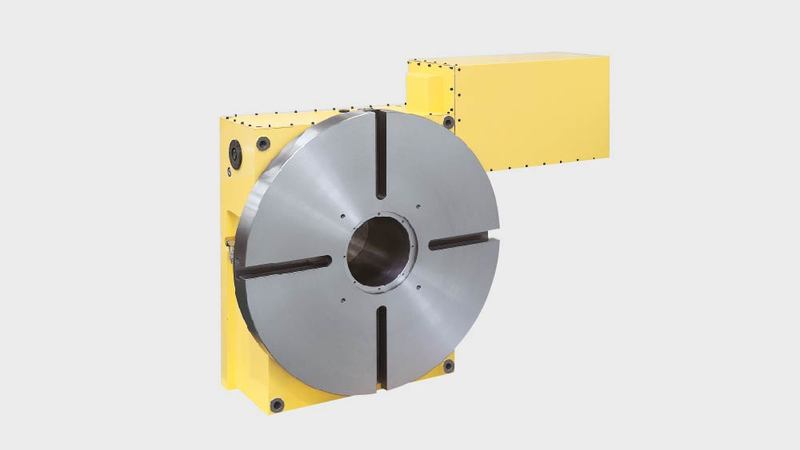

One of NIKKEN'S largest tables, the CNC1201 was designed exclusively for horizontal models, ideal for the aircraft and energy-related sectors.

Featuring a tooth thickness module of 10, a powerful clamping system and ultra-high rigidity, the CNC1201 offers unrivalled accuracy and longevity. Manufactured with high durability materials, the CNC1201 is designed to maintain high accuracy for the long term with minimal maintenance.

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

| CNC1201 | |

|---|---|

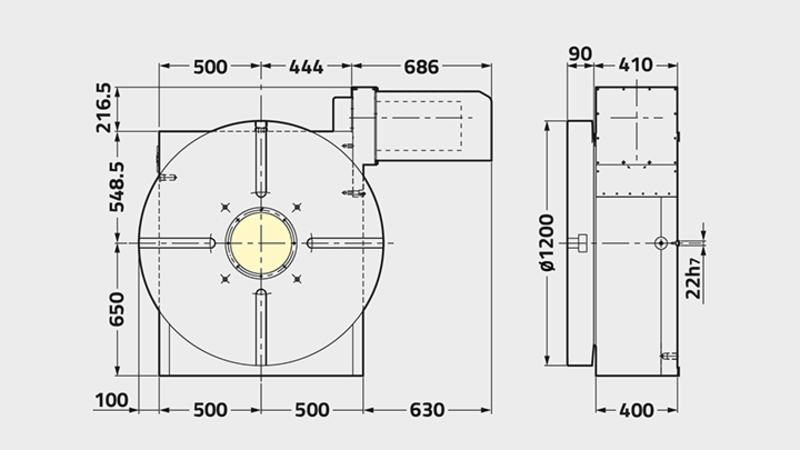

| Face Plate Diameter[Ømm] | 1200 |

| Table Range/Type | EXTRA LARGE |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 300 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | 650 |

| Width of T-Slot [mm] | 22 (Optional) |

| Clamping System | HYD |

| Clamping Torque [Nm] | 18000 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | N/A |

| Servo Motor [min1] | αiF30·2000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 2.7 |

| Total Reduction Ratio | 1/720 |

| Indexing Accuracy [sec] | 15 |

| Indexing Accuracy Ultra Precision [sec] | ±3 |

| Net Weight [Kg] | 3500 |

| Max. Vertical Work Load on Table [Kg] | 6500 |

| Max. Horizontal Work Load on Table [Kg] | 13000 |

| Max. Horizontal Thrust Load on the Table [N] | 1333330 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 79025 |

| Max. Thrust Load on the Table [FxL Nm] | 240000 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | N/A |

| Max. Work Inertia [Kg m2] | 2300 |

| Driving Torque [Nm] | 8640 |