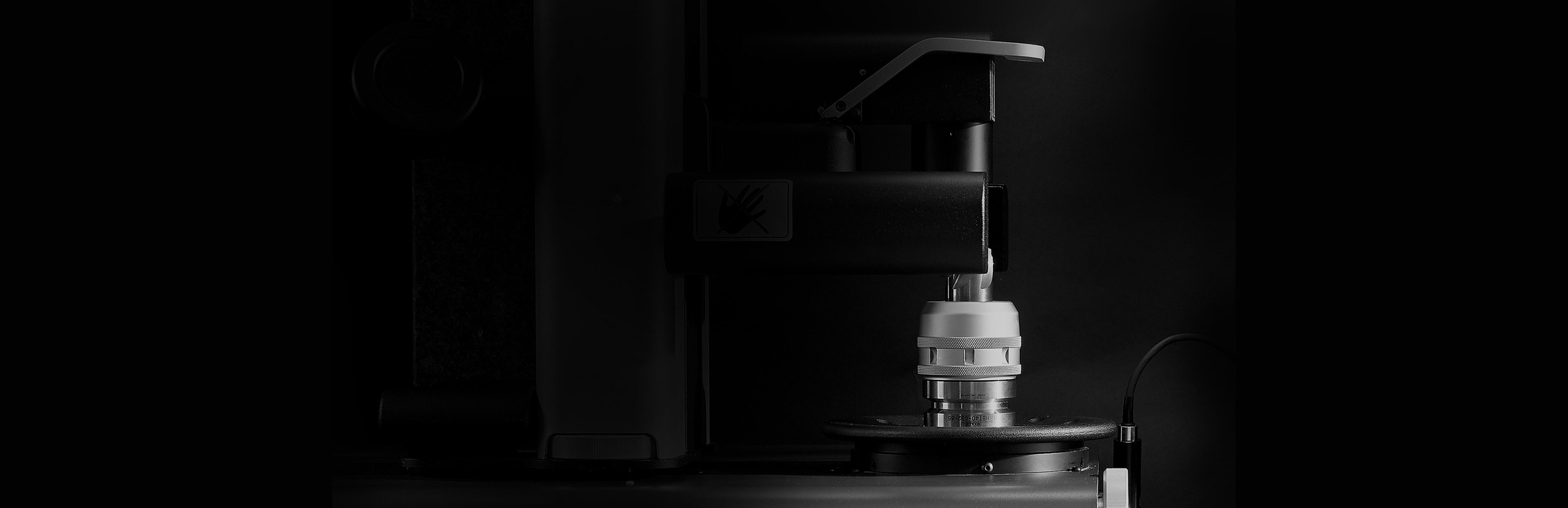

Our top of the range E68L Presetting machine has been developed from the ground up as the 'top level' specification option for our new generation of advanced tool presetting machines. Compared to the lower specification models, all quite capable in their own right, the construction, performance and design (particularly the electronic and software capability) provides considerable advantages.

Designed completely free-standing on its own integral base; E68L features ground granite and stainless steel construction combined with a large Twin Screen digital camera system with full industrial PC architecture – these electronics and software provide operational and functional simplicity that is second to none.

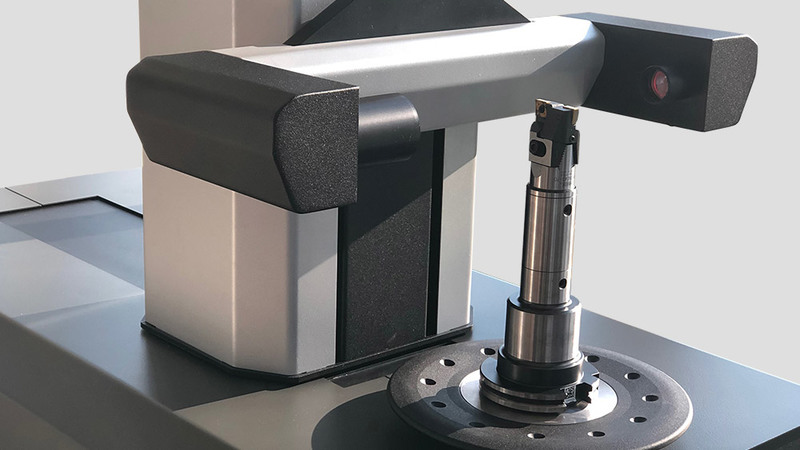

Featuring the ultimate high precision spindle system that is fully interchangeable and utilises a one-piece cartridge with full mechanical tool clamping (pneumatic system) capable of clamping ISO/BT, HSK and Polygonal taper tool shanks - eliminating the need for adaptors and the errors associated with their use. The construction of this system is more akin to a machine tool spindle than a tool presetter spindle!

-

All axis movements are servo controlled with absolutely no operator contact with the column.

-

Integrated within the innovative software package is a complete tool management system and network port.

-

DXF CAD profiles import and export function.

Axis Movemements

All axis movements on the E68L are servo controlled with absolutely no operator contact with the column. This drastically increases machine accuracy and repeatability over similar machines which incorporate the movement via a manual handle mounted on the column.

Software Package

Integrated within the innovative software package is a complete tool management system and network port. Working via your DNC system our software, as standard, converts measured tool data into CNC code for direct loading into the machine controller and associated tool offset pages.

Functionality

Further capabilities include the ability to import and export .DXF CAD profiles for detailed checking and comparison on the twin screen camera system.

E68L Series Brochure

(PDF - 10.9 MB)

E68L Tool Presetter

(PDF - 167 KB)

TECHNICAL DATA

Measuring range: Diameter max 600 mm (radius 300 mm); height max 800 mm.

Elbo Controlli NIKKEN linear transducers in optical glass directly mounted onto granite supports. Slide GS371 certified with HP laser. Axes resolution: X = 1μm, Z = 1μm.

Standard mechanical/electronic and optical equipment:

- Base and column made of natural granite to guarantee the maximum accuracy: linearity max Error 2 μm/Mt – certification with Taylor Hobson res.1 μm/Mt. electronic millesimal level. Monoblock machine structure in steel, floor mounted with 4 vibration damper adjustable supports.

- ISO / BT / HSK / VDI... etc. Interchangeable rotating spindle-holder (to be specified) max run-out error < 2 μm.

- Spindle Index in four angular positions: 0°-90°-180°-270°.

- Spindle-holder Identification System (SP-ID) with NFC technology to automatically identify the spindle-holder after each replacement.

- Linear slideways: 2 for X axis slideways and 1 for Z axis slideway.

- Double re-circulating ball bearing slides (five in total), lubricated for life. Universal motorised mechanical tool clamping (ISO/BT/HSK/polygonal taper tooling – to be specified).

- Pneumatic-mechanical braking of the spindle-holder rotation with 3 pistons at 120° position.

- Motorized axis movement.

- Control panel with micrometric handwheels and rapid movement buttons (2.5 m/mm).

- Constant load Archimedean spiral spring (as opposed to a mass counter-balance system).

Vision-system for tool measuring and cutting inspection consisting of:

- C-MOS sensor – Framed image area 8 x 8 mm.

- Magnification around 32X.

- Bi-telecentric lens.

- Illuminator: episcopic ring-light LED’s, diascopic telecentric lenses spot-light red.

Machine operator interface through:

- Full HD LCD 22” colour Touch Screen monitor.

- Intel Quad Core Processor.

- UBUNTU LINUX LTS operating system.

- Data storage on solid state disk SSD.

- Four USB ports.

- One LAN networking port and wireless connection.

Standard software:

- Operator-machine interface simple and intuitive by single screen function (based on ISO7000).

- Ease of use thanks to the integrated touchscreen.

- CNC machine origin and spindle adaptor management.

- Tool list creation and/or single tool. Also possibility to create a customized format.

- Theoretical measurement and tolerance management.

- Tool set and Post Processor universal generator.

- Automatic change of CNC machine origin allocation.

- Printable tool set report.

- DXF format drawings import capability for overlaying a drawing on a live tool profile.

- Tool profile acquisition exportable in DXF format.

- Ready for TID infrastructure for tool identification and data transfer using a data matrix tag/code.

- Ready for Magnetic chip code-holders (Balluff for example, hardware not included and available as option).

- Double OS and twin monitor option available to provide integration with Elbo Controlli NIKKEN TP32 management software.

- Anti-dust cover provided for when not in use.

Overall dimensions: Length = 1700 mm, Height = 2300 mm, Depth = 700 mm. Net weight: 570 Kg.

| E68L | |

|---|---|

| X Axis Measure (Diameter) | 600 |

| Z Axis Measure (Length) | 800 |

| Natural Granite Base & Column | ✓ |

| Interchangeable Spindle Cartridge | ✓ |

| C Axis Display Spindle Body and Spindle Cartridge | ✓ |

| Interchangeable Spindle Max. Run-Out Error | 2µm |

| Automatic Rotation of the Spindle | ✗ |

| Spindle Index in four Angular Positions (0º, -90º, -180º, -270º) | ✓ |

| Spindle Rotation Brake | Pneumatic 3 pistons @ 120º |

| Spindle Identification System (NFC recognition) | ✓ |

| Clamping System | Mechanic |

| Tool Inspection Function/Capability | ✓ |

| Elbo Controlli NIKKEN Triple Camera System (Cutting Edge Inspection) | ✗ |

| Main Camera System Resolution | ✗ |

| Main Camera System Measuring Range (C-MOS Sensor Framed Image Area) | 8mm x 8mm |

| Secondary 'Twin' Camera System Measuring Ranges (Framed Image Area) | ✗ |

| Main Camera Magnification | 32X |

| Secondary 'Twin' Camera System Magnifications | ✗ |

| Elbo Controlli NIKKEN Certified Optical Scale Axes Resolution | ✗ |

| Elbo Controlli NIKKEN GS371 Certified 'Natural Granite' Optical Scale Axes Resolution | 1µm |

| Touch Screen System (Operator Interface) | TFT 22" HD Colour Touch Screen |

| Keyboard and Mouse | ✓ |

| Electronics/Processor | Industrial Motherboard with Intel Processor |

| Firmware/Operating System | Ubuntu Linux LTS |

| Data Storage | SSD |

| Elbo Controlli NIKKEN Tool Management Software | E68L software |

| Tool Set Management and Post Processor Universal Generation | ✓ |

| DXF File Import and Creation | ✓ |

| Balluff Read/Write Ready (Balluff Hardware Required)? | ✓ |

| Elbo Controlli NIKKEN TiD Ready? | ✓ |

| Elbo Controlli NIKKEN TP32 Ready? | ✓ |

| Elbo Controlli NIKKEN IS 'Integrated Solution' with Twin Screen and Dual OS Option Ready? | ✗ |