NIKKEN Rotary Tables: 3 Key CNC Benefits

Reducing costs, increasing productivity and striving towards more sustainable practices are all any engineering company wants.

NIKKEN Rotary Tables continue to lead the market, setting the gold standard for what manufacturers should expect from their rotary table solutions. Whether you're upgrading an existing setup or outfitting a brand-new production line, here are three compelling reasons why choosing a NIKKEN Rotary Table is a smart investment:

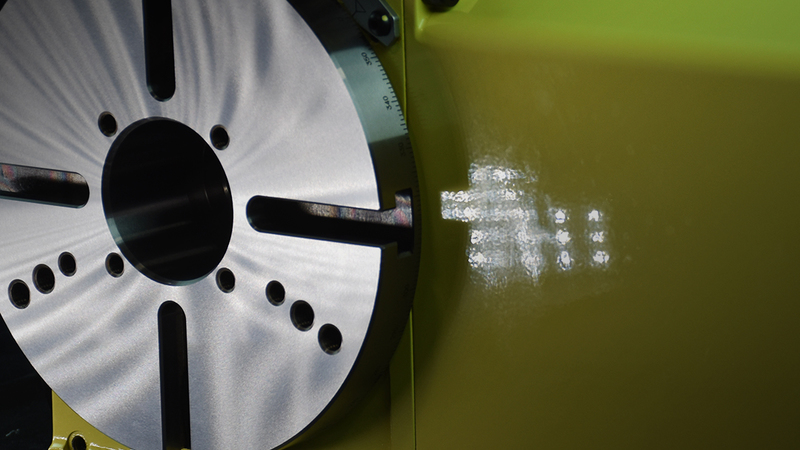

Unrivalled Accuracy and Engineering Excellence

NIKKEN’s rotary tables are built with proprietary technology that delivers unmatched performance and precision. With unique, internally developed manufacturing processes and construction techniques, like the exclusive Carbide Worm Screw, Ion Nitrided Hardened Steel Worm Wheel system, Solid radial roller bearings and Hollow axial support bearings customers are able to optimise their capabilities whilst benefitting from minimal backlash and optimum rigidity - even under high-load conditions to meet every demand and process. These groundbreaking innovations allow users to fine-tune their operations with confidence and reliability.

.jpg)

Versatile Solutions for Every Requirement

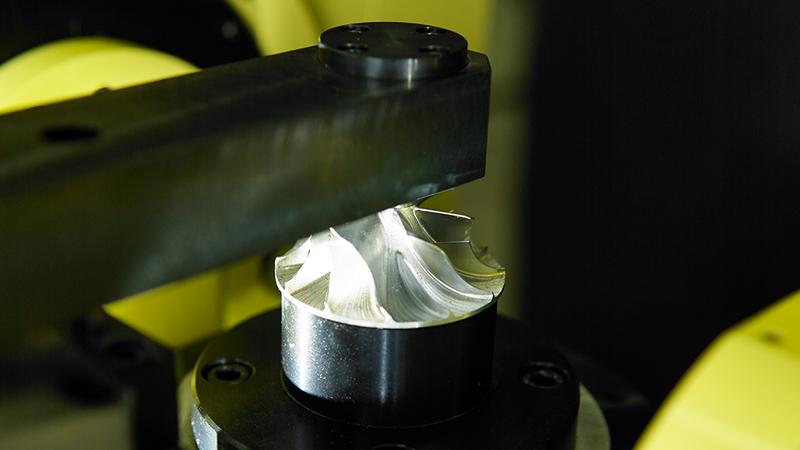

From worm and wheel Single Axis (4th), Twin Axis (5th), Multi-Spindle, Standard Speed and High-Speed Drive rotary tables to Barrel Cam and Direct Drive setups, NIKKEN offers one of the most extensive and adaptable ranges of rotary tables in the world.

Every table can be configured for direct CNC control or paired with NIKKEN’s exclusive Alpha 21 controllers for advanced functionality, including precise positioning and full Macro B control. In addition, NIKKEN can provide an extensive range of ‘added value’ accessories, such as bespoke trunnions & work holding solutions, chucks, vices, tailstocks and supports- meaning we can offer a perfect fit for any machine tool or production demand.

A standout innovation is the HSR-DD Table with hybrid machining provided by our new turning function for compatible machines and controllers. This impressive solution benefits customers by adding a multi-tasking capability to a conventional machining centre to optimize production and reduce costs! The NIKKEN HSR Rotary Table range use built-in direct drive motors to achieve a high-speed positioning and rotation speed of 1500r/min for the Rotary Axis! This innovation not only allows turning and machining processes on a single machine but also features our patented core cooling system for the Rotary spindle which suppresses temperature rise and increases reliability during continuous cutting operations.

Built-In Sustainability and Long-Term Value

In a market where machine downtime and maintenance costs can severely impact profitability our rotary tables offer true peace of mind. ALL NIKKEN Rotary Tables provide durability, low maintenance, and sustainability, thanks to our exclusive heat treatment processes, component design and optimized construction elements all being focused on longevity.

This attention to detail ultimately results in peak performance for the product's life.