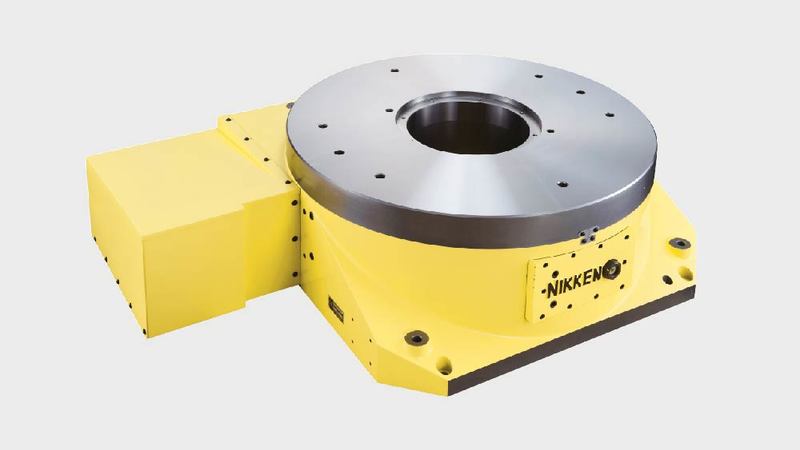

An ideal solution for machining oil and natural gas boring pipes, the built-in CNC802 Ultra Big Bore is designed for accuracy, high performance, easy maintenance and life long durability.

Allowing the component to pass through the centre and featuring an incredibly powerful hydraulic clamping system, the CNC802 offers high strength and rigidity.

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

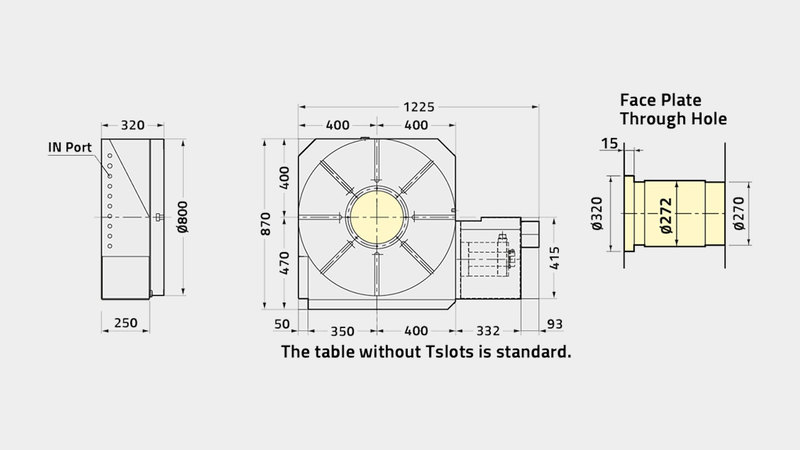

| CNC802 | |

|---|---|

| Face Plate Diameter[Ømm] | 800 |

| Table Range/Type | BUILT-IN |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 270 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | N/A |

| Width of T-Slot [mm] | N/A |

| Clamping System | HYD |

| Clamping Torque [Nm] | 7000 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 5.3 |

| Servo Motor [min1] | αiF22·2000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 5.5 |

| Total Reduction Ratio | 1/360 |

| Indexing Accuracy [sec] | 15 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 1100 |

| Max. Vertical Work Load on Table [Kg] | N/A |

| Max. Horizontal Work Load on Table [Kg] | 3000 |

| Max. Horizontal Thrust Load on the Table [N] | 247920 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 8563 |

| Max. Thrust Load on the Table [FxL Nm] | 36260 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | N/A |

| Max. Work Inertia [Kg m2] | 234 |

| Driving Torque [Nm] | 3168 |