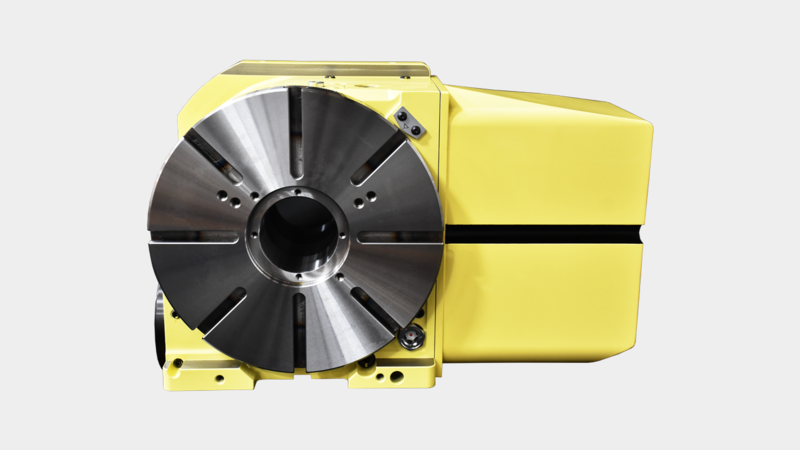

The CNC302PLUS is NIKKEN’s latest Rotary Table with a completely reimagined and updated clamping system.

This new internal design takes better advantage of standard pneumatic supplies, enabling various applications to be machined without the need of an additional hydraulic power pack.

This table is commonly used on a wide range of vertical machining centres to provide 4th axis capabilities at a minimal outlay whilst providing optimum NIKKEN reliability, making it a very sustainable investment.

The brake system can generate a clamping torque of 1430Nm, which is 2.4 x more powerful than the original CNC302 (1430Nm is achieved from a 5 Bar air supply with 1550Nm being possible from a typical 6 Bar workshop supply)!

The CNC302PLUS makes a great solution to maximise the use of your machining centre and can be mounted vertically or horizontally, to suit any application.

NIKKEN CNC Rotary Tables

(PDF - 26.3 MB)

| CNC(Z)302P | |

|---|---|

| Face Plate Diameter[Ømm] | 302 |

| Table Range/Type | STANDARD |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 80 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | 170 |

| Width of T-Slot [mm] | 12 |

| Clamping System | PNEUMATIC |

| Clamping Torque [Nm] | 1430 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 0.33 |

| Servo Motor [min1] | αiF4·3000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 25.0 |

| Total Reduction Ratio | 1/120 |

| Indexing Accuracy [sec] | 20 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 120 |

| Max. Vertical Work Load on Table [Kg] | 175 |

| Max. Horizontal Work Load on Table [Kg] | 350 |

| Driving Torque [Nm] | 192 |