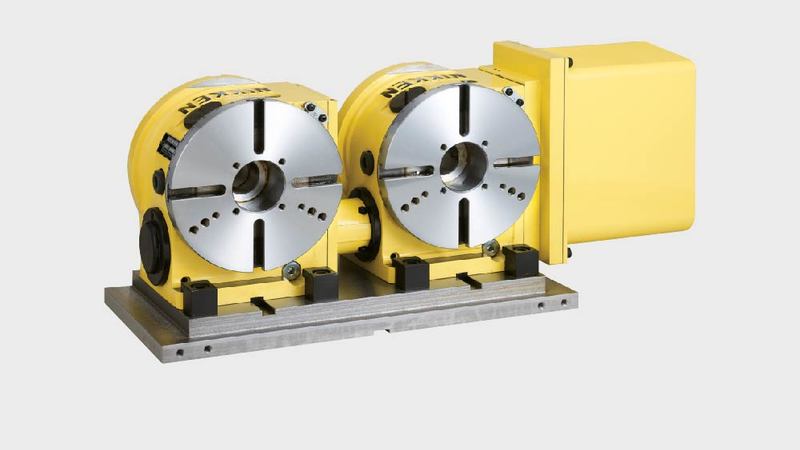

The NIKKEN CNC202-TW delivers outstanding performance levels for a pneumatically clamped Multi-Spindle CNC Rotary Table. whilst enhancing capacity and process allowing you to mass-produce components in fewer setups.

With the ability to multi-load parts, the CNC202-2W is ideal for manufacturing small items and mass-producing parts.

The inclusion of the multiple spindles for the construction of the CNC202-2W make absolutely no compromise to performance and, just like the rest of the NIKKEN CNC Rotary Table range, promises to enhance productivity while maintaining unrivalled high precision, high rigidity and durability.

The CNC202-2W is also available with a high-speed motor that can quickly deliver a substantial return on investment.

The rotary table can be supplied with a range of motors and controllers to meet your specific requirements - see the downloads section for more information or contact us to learn more.

Nikken Rotary Table Catalogue

(PDF - 26.3 MB)

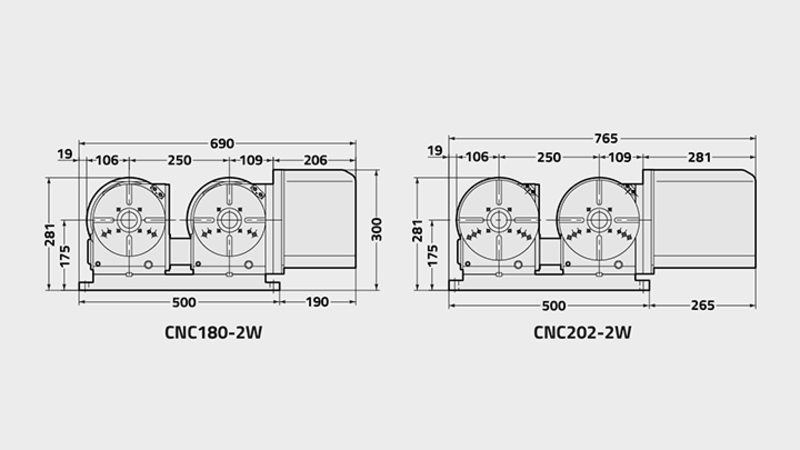

| CNC202-2W | |

|---|---|

| Face Plate Diameter[Ømm] | 200 |

| Table Range/Type | MULTI-SPINDLE |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 60 |

| Number of Spindles x Pitch [mm] | 2 x 250 |

| Centre Height [mm] | 175 |

| Width of T-Slot [mm] | 12 |

| Clamping System | AIR |

| Clamping Torque [Nm] | 303 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 0.13 |

| Servo Motor [min1] | αiF8·3000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 33.3 |

| Total Reduction Ratio | 1/90 |

| Indexing Accuracy [sec] | ±20 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 120 |

| Max. Vertical Work Load on Table [Kg] | 100 |

| Max. Horizontal Work Load on Table [Kg] | 200 |

| Max. Horizontal Thrust Load on the Table [N] | 18000 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 542 |

| Max. Thrust Load on the Table [FxL Nm] | 690 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | N/A |

| Max. Work Inertia [Kg m2] | 0.5 |

| Driving Torque [Nm] | 144 |