One of our larger rotary tables, the CNC1000 is designed for indexing and lead cutting large workpieces, making it the ideal Rotary Table for use in the Aerospace and energy-related industries.

Manufactured exclusively as horizontal models, featuring a tooth thickness module of 10, powerful clamping system and ultra-high rigidity the CNC1000 is designed to maintain precision and have longevity.

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

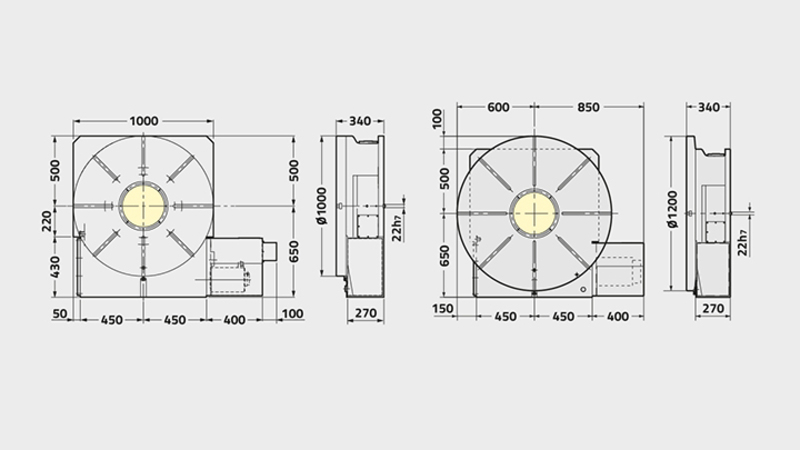

| CNC1000 | |

|---|---|

| Face Plate Diameter[Ømm] | 1000 |

| Table Range/Type | EXTRA LARGE |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 300 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | Horizontal Only |

| Width of T-Slot [mm] | 22 (Optional) |

| Clamping System | HYD |

| Clamping Torque [Nm] | 18000 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | N/A |

| Servo Motor [min1] | αiF22·2000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 5.5 |

| Total Reduction Ratio | 1/360 |

| Indexing Accuracy [sec] | 15 |

| Indexing Accuracy Ultra Precision [sec] | ±3 |

| Net Weight [Kg] | 1700 |

| Max. Vertical Work Load on Table [Kg] | N/A |

| Max. Horizontal Work Load on Table [Kg] | 7000 |

| Max. Horizontal Thrust Load on the Table [N] | 281250 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 24080 |

| Max. Thrust Load on the Table [FxL Nm] | 42190 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | N/A |

| Max. Work Inertia [Kg m2] | 1300 |

| Driving Torque [Nm] | 3168 |