The NIKKEN CNC321 uses hydraulic clamping for a clamping torque of 1760Nm with an average of 22.2RPM.

With the ability to be used vertically or horizontally, depending on the application, the CNC321 makes a great solution to maximise the use of your machining centre.

The CNCZ321 comes with a high-speed motor as standard that can quickly deliver a substantial return on investment.

The rotary table can be supplied with a range of motors and controllers to meet your specific requirements - see the downloads section for more information or contact us to learn more.

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

| CNC(Z)321 | |

|---|---|

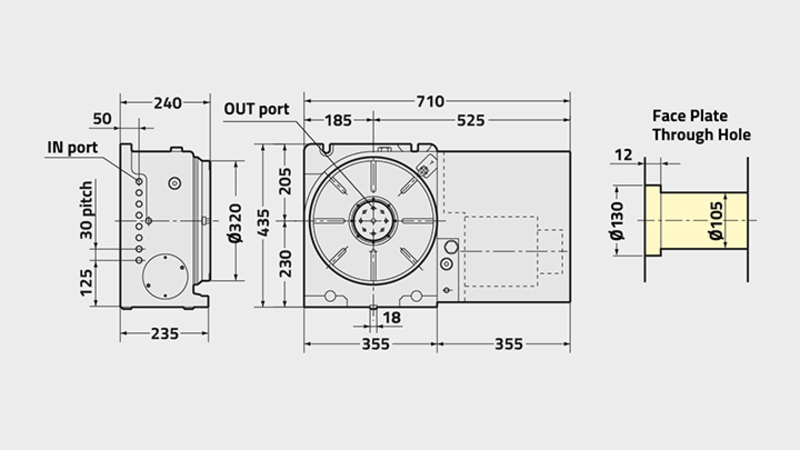

| Face Plate Diameter[Ømm] | 320 |

| Table Range/Type | STANDARD |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 105 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | 230 |

| Width of T-Slot [mm] | 12 |

| Clamping System | HYD |

| Clamping Torque [Nm] | 1760 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 2.8 |

| Servo Motor [min1] | αiF12·2000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 22.2 (44.4) |

| Total Reduction Ratio | 1/90 (1/45) |

| Indexing Accuracy [sec] | 15 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 200 |

| Max. Vertical Work Load on Table [Kg] | 250 |

| Max. Horizontal Work Load on Table [Kg] | 500 |

| Max. Horizontal Thrust Load on the Table [N] | 53100 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 2648 |

| Max. Thrust Load on the Table [FxL Nm] | 3840 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | 100 |

| Max. Work Inertia [Kg m2] | 6.4 (3.4) |

| Driving Torque [Nm] | 432 (345) |