The CNC260 is the most versatile Rotary Table ever produced by NIKKEN. This table is commonly used on a wide range of vertical machining centres to provide 4th axis capabilities at minimal costs.

The table can be installed with a standard air brake or can be equipped with a hydraulic braking system which virtually triples the clamping torque to a massive 1568 Nm.

With the ability to be used vertically or horizontally, depending on the application, the CNC260 makes a great solution to maximise the use of your machining centre.

The CNC260B motor is mounted to the backside of the rotary table whereas the CNC260 motor can be mounted to the left or right.

The CNCZ260B comes with a high-speed motor as standard that can quickly deliver a substantial return on investment.

The rotary table can be supplied with a range of motors and controllers to meet your specific requirements - see the downloads section for more information or contact us to learn more.

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

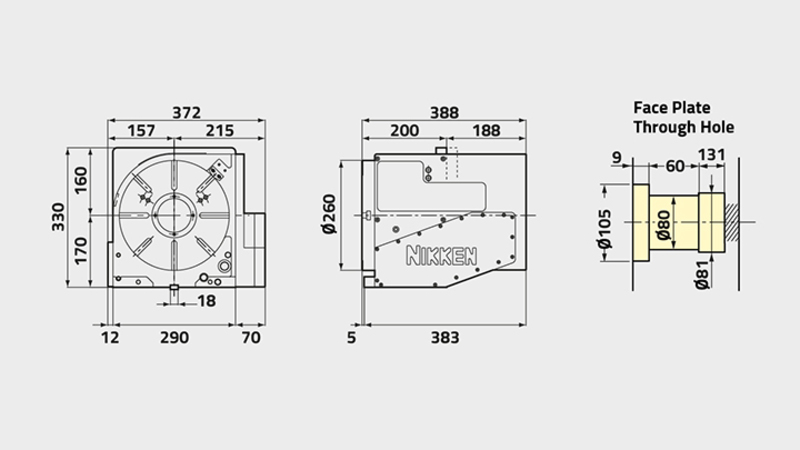

| CNC(Z)260B | |

|---|---|

| Face Plate Diameter[Ømm] | 260 |

| Table Range/Type | STANDARD |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | REAR |

| Diameter of Spindle Hole [Ømm H7] | 80 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | 170 |

| Width of T-Slot [mm] | 12 |

| Clamping System | AIR/HYD |

| Clamping Torque [Nm] | 588/1568 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 1.7 |

| Servo Motor [min1] | αiF4·3000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 25.0 (50.0) |

| Total Reduction Ratio | 1/120 (1/60) |

| Indexing Accuracy [sec] | 20 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 145 |

| Max. Vertical Work Load on Table [Kg] | 175 |

| Max. Horizontal Work Load on Table [Kg] | N/A |

| Max. Horizontal Thrust Load on the Table [N] | 42480 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 1442 |

| Max. Thrust Load on the Table [FxL Nm] | 2320 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | 50 |

| Max. Work Inertia [Kg m2] | 3.2 (1.6) |

| Driving Torque [Nm] | 192 (153) |