The NIKKEN CNC202 is a favourite with manufacturers of vertical machining centres. This NIKKEN classic delivers outstanding performance levels for a pneumatically clamped rotary table.

With a small footprint, it could prove to be exactly the solution you need to turn your existing machining centre into a fourth-axis workhorse delivering a substantial return on investment while enabling you to take on a myriad of new jobs that were previously "out of reach".

The CNCZ202 comes with a high-speed motor as standard that can quickly deliver a substantial return on investment.

The rotary table can be supplied with a range of motors and controllers to meet your specific requirements - see the downloads section for more information or contact us to learn more.

202-.jpg)

Nikken Rotary Table Catalogue – 2019

(PDF - 26.3 MB)

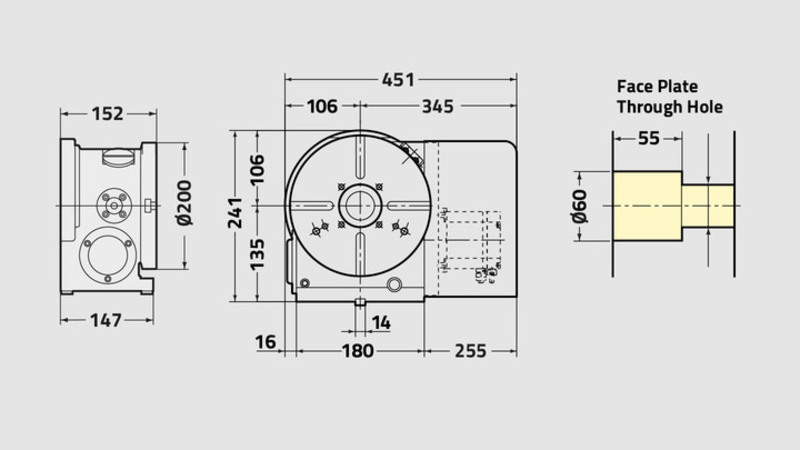

| CNC(Z)202 | |

|---|---|

| Face Plate Diameter[Ømm] | 200 |

| Table Range/Type | COMPACT |

| Standard Motor Orientation (Left Hand Option Available for Right Hand Tables) | RIGHT |

| Diameter of Spindle Hole [Ømm H7] | 60 |

| Number of Spindles x Pitch [mm] | 1 |

| Centre Height [mm] | 135 |

| Width of T-Slot [mm] | 12 |

| Clamping System | AIR |

| Clamping Torque [Nm] | 303 |

| Table Inertia at Motor Shaft [Kg m2 x 103] | 0.09 |

| Servo Motor [min1] | αiF4·3000 |

| Min. Increment [Degrees] | 0.001 |

| Rotation Speed [min1] | 33.3 (66.6) |

| Total Reduction Ratio | 1/90 (1/45) |

| Indexing Accuracy [sec] | ±20 |

| Indexing Accuracy Ultra Precision [sec] | N/A |

| Net Weight [Kg] | 55 |

| Max. Vertical Work Load on Table [Kg] | 100 |

| Max. Horizontal Work Load on Table [Kg] | 200 |

| Max. Horizontal Thrust Load on the Table [N] | 18000 |

| Strength of Worm Wheel Without Brake (Against Dynamic Cutting Thrust) [FxL Nm] | 542 |

| Max. Thrust Load on the Table [FxL Nm] | 690 |

| Guideline of Max. Unbalancing Load (Vertical with Support) [Nm] | 50 |

| Max. Work Inertia [Kg m2] | 1.0 (0.5) |

| Driving Torque [Nm] | 114 (115) |