Why Might YOU Need a Presetter?

Precision drives profit and downtime is the enemy, the real question isn’t whether you can afford a tool presetter, it’s whether you can afford not to have one.

Whether you're a growing workshop, a high-output production line, or anything in between, a tool presetter might just be the game-changer your operation is missing.

There are a multiple of reasons why a Presetter is necessary, here are a few:

- Because Time Is Money

If your machine operators are still measuring tools at the spindle, you're losing time and money, every single day. A presetter eliminates this waste by allowing you to measure and set up tools offline, while your machines keep running.

With Elbo Controlli NIKKEN’s range of standard and automatic presetters, you’ll drastically reduce setup and machine downtime.

- Because Automation = Freedom

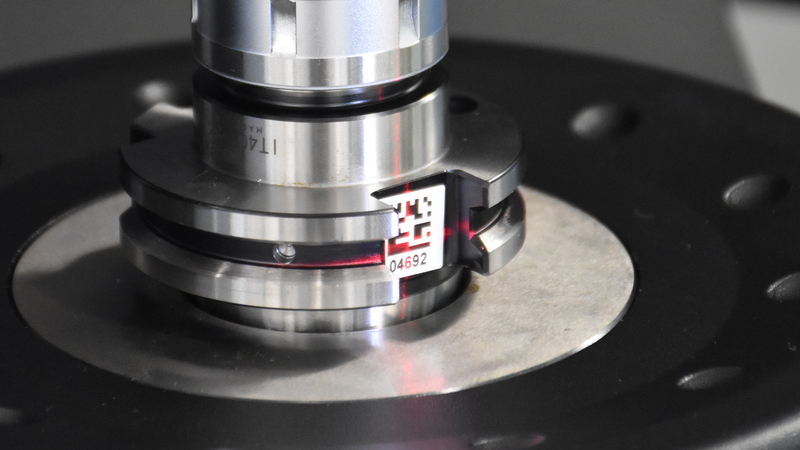

Our latest lineup, including models like the fully CNC-controlled E46CX, features powerful automation. From automatic vision system positioning to patented spindle rotation and smart geometry recognition, these machines reduce human error and let you focus on what matters most: making quality parts, faster.

And with a new touchscreen interface that feels more like a smartphone than a control panel, it makes the production process, simpler, faster and easier.

- Because Accuracy Isn’t Optional Anymore

Today’s parts demand tighter tolerances. Your customers expect perfection, and your machines are only as accurate as the data you feed them.

Our presetters, developed and manufactured at Elbo-Controlli NIKKEN in Italy, are built with the finest materials, right down to the bespoke optics, electronics, and even the natural granite base and column, for unbeatable dimensional stability and reliability, providing unmatched precision, every time.

- Future Proofing

Industry 4.0 isn't just a buzzword. It's the new benchmark for competitiveness. Elbo Controlli NIKKEN presetters are built with full networking and post-processing capabilities right out of the box- making it easy to connect with your CNC machines, cloud systems, and tooling databases, allowing you to manage your entire production system either from the tool room or directly on shop floor (or a mix of both). Total visibility, optimum control, and reduced waste- all contributing to a more sustainable manufacturing environment.

- Because Sustainability Is Also About Smarter Spending

NIKKEN presetters don’t just save you time- they’re cost-effective to operate, energy-efficient, and built to last. You’ll reduce tool wear, avoid expensive rework, and get more done with less.

It’s a long-term investment that pays off faster than you might think.

So... Do You Need a Presetter?

If you want to:

- Increase machine uptime

- Guarantee tool accuracy

- Simplify setup and reduce operator dependence

- Connect your workshop to a smarter future

- Improve productivity and sustainability...

...then the answer is yes.