The Process behind NIKKEN's Refurbished Rotary Tables

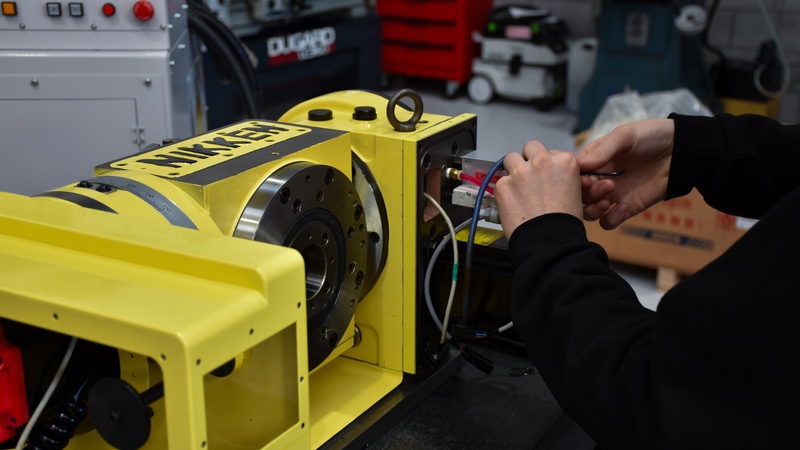

At the heart of our refurbishment service is a dedicated team of specialist engineers, committed to restoring NIKKEN Rotary Tables to the highest standards of quality and performance.

Leveraging our extensive stock of over one million spare parts, our experienced technicians perform complete mechanical rebuilds, starting with a full strip-down and ending with a product that closely mirrors its original condition, both in function and appearance.

Every refurbishment begins with a comprehensive functionality assessment. This initial check gives our engineers a clear understanding of the table's condition and helps guide the scope of the refurbishment process.

Next, the table is completely disassembled and each component undergoes an intensive deep clean. During this stage, parts are meticulously inspected, and any that are worn or damaged are flagged for replacement. All castings, covers, and external surfaces are sent for thorough degreasing and professional powder coating to restore their finish.

As part of our standard refurbishment protocol, we replace all bearings, seals, o-rings, gaskets, oil sight glasses, oils, and greases. Critical components such as the worm screw, worm gear, and braking elements are also replaced when necessary to ensure peak operational performance.

Once reassembled, the refurbished table undergoes a rigorous series of functionality and alignment checks using our in-house Coordinate Measuring Machine (CMM). This final stage ensures each unit meets stringent tolerances and performs as closely as possible to its original factory specifications.

EXTENDED WARRANTY

To give you peace of mind, all of our refurbished rotary tables now come with the same 12-month standard warranty as all of our new rotary tables.

LEARN MORE ABOUT OUR RANGE OF REFURBISHED TABLES