The Next Generation of Mini-Mini

At NIKKEN we pride ourselves in constantly exploring new and innovative ways to develop our expansive range of products. This also includes looking back on our classic solutions to ensure they remain a competitive choice within the industry.

The Mini-Mini Advanced Alpha is the latest in a series of redesigns based around our 8 degree collet system, allowing for ultimate gripping force while remaining a compact solution.

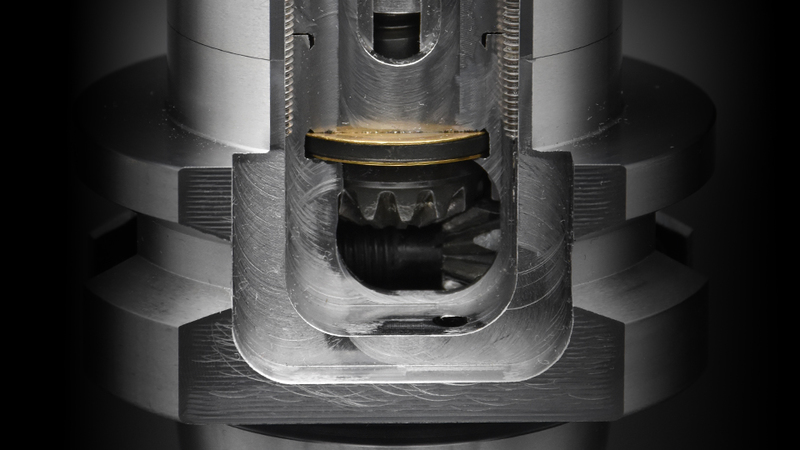

The internal construction, which retains our extended collet featuring a precise ‘pilot’ location diameter with a threaded bore at the rear, has now been now updated to include our innovative TiN bearing system for improved clamping and gripping. Once loaded into the holder the collet engages with an internal draw bar and is pulled backwards to collapse the ID and clamp the cutting tool. This eradicates the requirement for an external clamping nut and its associated thread, allowing for a more compact and rigid option compared to a traditional collet chuck.

The ideal solution for high speed without compromising on rigidity, the application options for the Mini-Mini are wide and varied. Options are available to suit all processes with choices for shank size, length and configuration.

MINI-MINI ADVANCED ALPHA BROCHURE

(PDF - 60.3 MB)

For optimal application the Mini-Mini Advanced Alpha is available in two designs:

- A standard ‘AA’ version featuring twin internal bevel gears for clamping. The first ‘drive’ gear is accessed with the clamp key from the side of the holder with the second, rotated by the drive gear and integral to the drawbar, drawing and clamping the collet.

- The alternate ‘AT’ design has been created mainly for HSK tapers. Simpler in construction, AT features direct clamping using only a single internal ‘Direct Screw’ drawbar. The clamp key is extended and accesses the drawbar from the rear of the taper to directly clamp the collet.

LEARN MORE ABOUT OUR RANGE OF TOOLHOLDERS