The Integrated Solution

The "Fourth Industrial Revolution" has brought on a significant change in the world of manufacturing, potentially transforming all aspects of the productive process. Automation and interconnection are the keywords of Industry 4.0, leading to the development of machines and systems that can easily communicate with each other, to simplify the control and management of machinery and related systems.

This latest advancement pushed Elbo Controlli NIKKEN to develop their new E46L IS, E46LA IS, E68L IS, and E68LA IS presetter machines (Integrated Solution). These new products are the integrated solutions for toolroom: all the machines are equipped with TP32 (Integrated Tool Management System) and TID(Automatic Tool Identification System). This allows complete management of the toolroom, significantly reducing production costs and optimizing the material supply system.

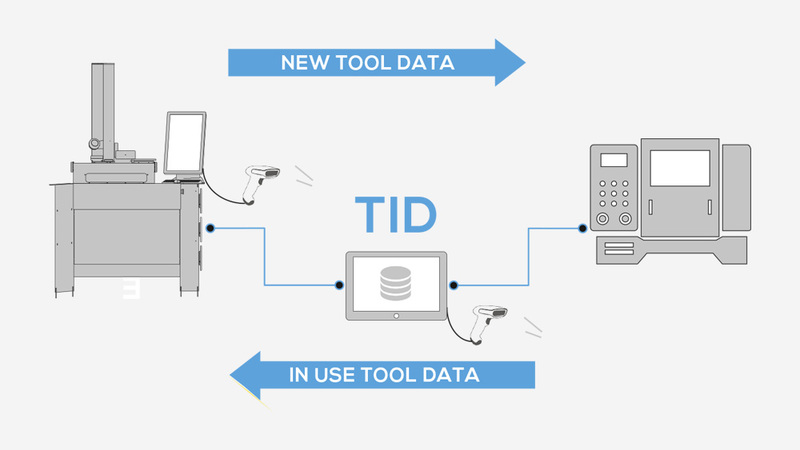

Elbo Controlli NIKKEN's TID system allows two-way communication between the presetting machine and the CNC, sending the measurement directly to numerical control, negating downtime.

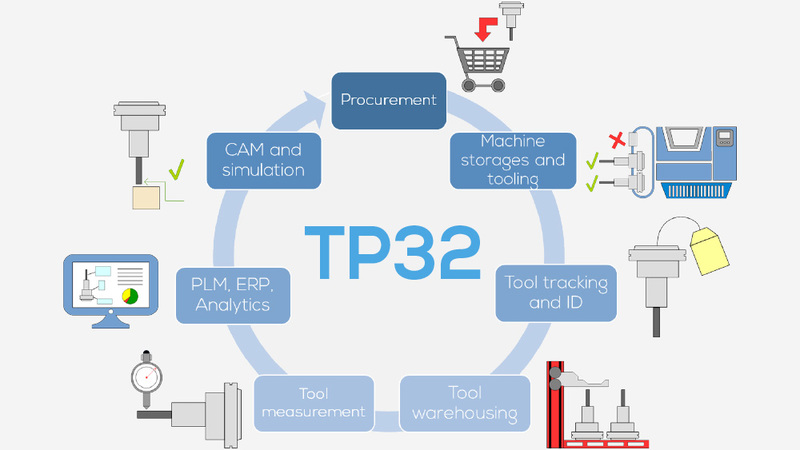

Likewise, our advanced TP32 system manages the production system entirely as a fundamental component of the production cycle. TP32 allows full control of the manufacturing, warehouse and stock situations, managing and controlling entire tool assemblies, their location within the factory and individual components and elements.

All the IS presetter machines are equipped with two 22" Full HD vertical touch screen monitors:

The primary monitor (left) is dedicated to all presetting and tool measurement functions

The secondary monitor (right) has been developed for TP32 tool management and TID tool identification