NIKKEN Multi-Lock utilised for James Webb Telescope

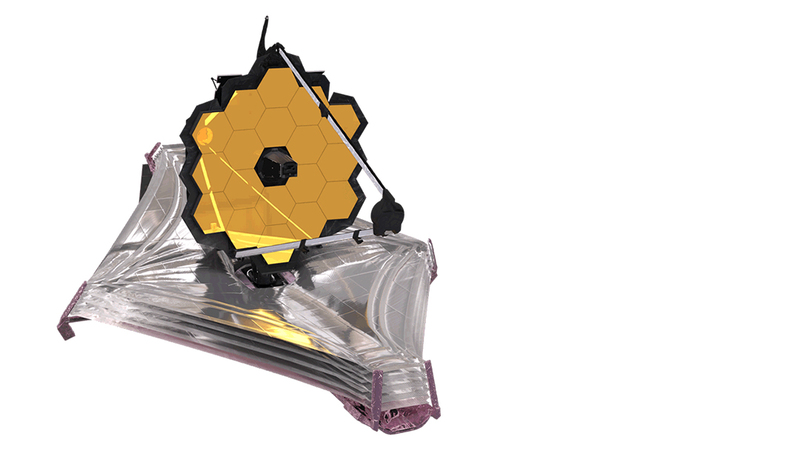

The James Webb Space Telescope, NASA's highly anticipated successor to the Hubble Space Telescope, has successfully launched on December 22, 2021. The telescope is poised to become one of the most influential scientific instruments ever built, with the capability to revolutionise our understanding of the universe. The telescope is designed to observe the universe in the infrared spectrum, allowing it to see through dust and gas clouds obstructing visible light.

The James Webb Space Telescope is also equipped with a 21-foot (6.5-meter) primary mirror, which is more than twice the size of Hubble's mirror, enabling the telescope to capture lighter and provide higher-resolution images.

NIKKEN are delighted to be a part of the manufacturing process behind James Webb's telescope with NIKKEN's world-leading Multi-Lock, being used to help manufacture the 18 hexagonal segments, which all align to focus light and act as one giant mirror. The Multi-Lock Milling Chuck offers an incredible 80-85% taper contact, better than AT3 standard, offering the spindle guarantee, increasing accuracy and reducing the spindle motor load and ultimately consuming less energy and energy, improving sustainability. Thus, proving the perfect tool holder to produce such a large and intricate piece of equipment.

The Multi-Lock was first introduced to Axsys almost 8 years ago when the Very Large Telescope (VLT) mirror program had only just started. Axsys is a design, manufacture and inspection company focused on providing the best possible hardware/software technology available for products, parts and tooling.

Axsys were struggling with finding a tool holder that could eliminate the need for flats on the end mill shanks while increasing tool strength and turned to the world-renowned Multi-Lock to help them succeed. Axsys employed end mills with 0.750-inch diameters to remove large amounts of material in the process that NIKKEN tool holders supported. The 80-85% taper contact prevented the tool from pulling out during machining operations, creating a smoother surface finish. Causing Axsys to eventually replace all their previous holders with new NIKKEN Multi-Lock Milling Chucks.

Axsys: http://www.axsysinc.com

James Webb Telescope: https://webb.nasa.gov