Industry 4.0 Integration: NIKKEN I/O

At NIKKEN we believe in innovation everywhere in our product lifecycle, this is why we are utilizing the latest, cloud-based technology to monitor data during the lifetime of our solutions.

Offering you full Industry 4.0 compliance, we’ve designed a new passive, continuous, condition monitoring system (NIKKEN I/O) that runs day in, day out to ensure that you are kept up-to-date on the running of your NIKKEN products. We monitor your rotary table investment, so you don’t have to, saving you time and money in unnecessary maintenance and downtime.

Being able to sense and predict failure is a major asset to both the end-user – in maintaining uptime of machines, and to NIKKEN itself – to ensure we are providing the best solution possible for our partners.

Nikken I/O is a sensor box that fits inside your rotary table, passively performing:

- Crash detection

- Overcurrent detection

- Uptime monitoring

- Usage monitoring

The Process of NIKKEN I/O

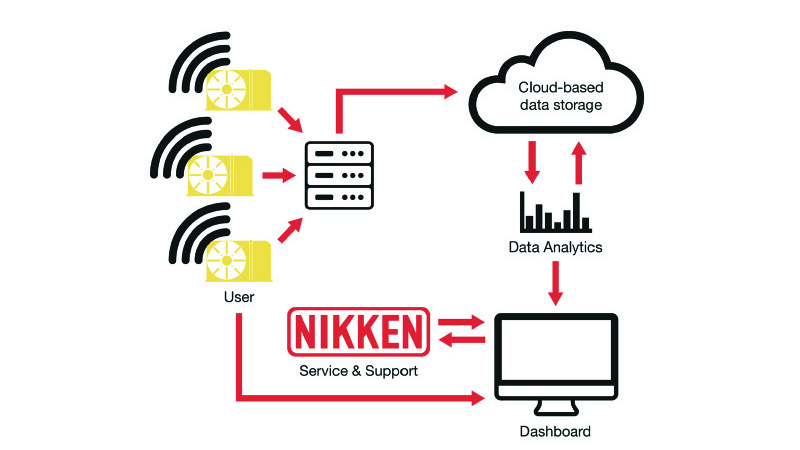

- Sensors inside the rotary table capture real time data wirelessly while in production.

- A receiver on the workshop floor receives this data, performs the required processing, and enters it into a database.

- A custom, standalone web-based dashboard accesses this database to provide rich, customizable data visuals with an at a glance flagging system, so you can see the beginning of an issue before it becomes a fault.

Running over wi-fi, NIKKEN I/O can be connected to any local network, or even as a global cloud-based solution.

SERVICING BASE PLUGIN AS STANDARD:

- Backlash measurement

- Collision detection

- Current measurement, showing actual power trace of the rotary table during production

- Uptime and usage measurement

ADDITIONAL OPTIONS:

- Vibration monitoring, providing frequency information to aid operators in reducing vibration uniquely on the rotary workpiece.

- Oil condition monitoring.

LEARN MORE ABOUT THE BENEFITS OF NIKKEN I/O