How Tool Management Can Save You Money and Time!

TP32 Tool Management, Tool ID (TiD), and Tool Tracking System (TTS) were developed to meet the evolving demands of smart manufacturing and using connectivity between systems to improve information exchange and streamline processes.

These systems provide system integration, leading to improved visibility and efficiency that empower manufacturers to maximise uptime, reduce waste, and centralise critical data.

Built as a comprehensive, fully integrated tool management solution, TP32 brings unmatched visibility and data exchange to the shop floor. Designed for seamless connectivity with CAM systems, CNC machines, ERP software, vending systems and more, TP32 manages every tool and resource within a production environment, ensuring nothing is misplaced or overstocked, and all usage and costs are visible.

Key Features & Benefits of TP32:

- Full Warehouse & Tooling Control – Monitor and manage tool holders, cutting tools, inserts, and consumables.

- Zero Downtime – Real-time stock visibility means the right tool is always on hand, when needed.

- Total Cost Tracking – Optimise procurement and understand tooling costs with total transparency.

- Machine Integration – Includes tool table management, ISO13399 library compatibility, CADCAM linking, and tool verification.

- Customisable & Scalable – Open database architecture allows adaptation to any production workflow.

From the tool room to purchasing, TP32 delivers a user-friendly interface that empowers teams to work smarter with consolidated inventories, simplified tool data management, and streamlined assembly control.

Customers are invited to explore the full potential of TP32 with a free consultation at NIKKEN’s state-of-the-art Innovation Centre.

“TP32 isn’t just software; it’s a foundation for modern manufacturing. It transforms your production cycle by eliminating inefficiencies and giving every department access to the same accurate, real-time information”- Nathan Ray Deputy Managing Director.

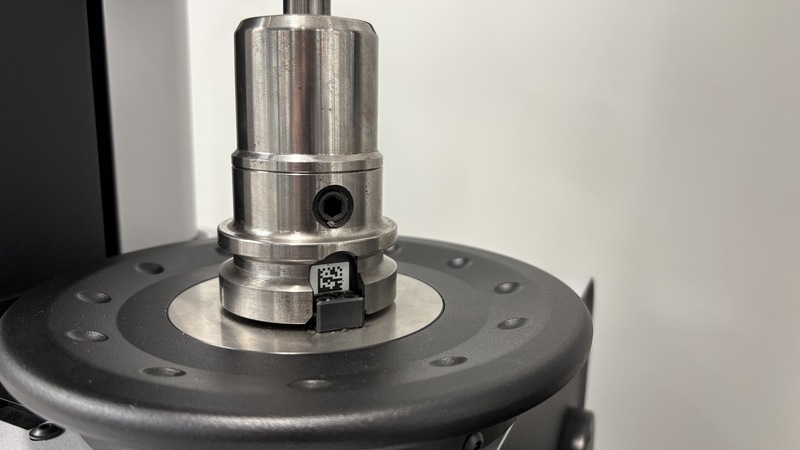

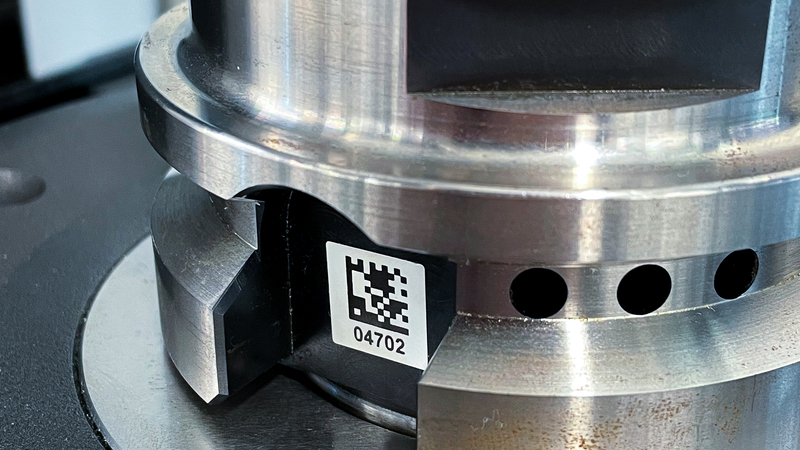

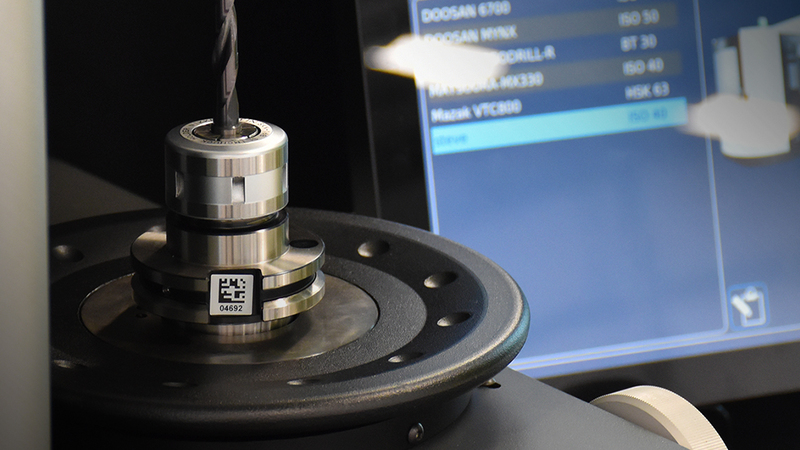

TiD: Tool Identification Made Simple

For manufacturers seeking a reliable entry point into digital tool data management, NIKKEN’s TiD (Tool ID Manager) is the ideal solution. Developed by Elbo Controlli NIKKEN, TiD is a cost-effective, plug-and-play system for managing tool identification and data transfer.

How It Works:

TiD utilises handheld scanners to read a data matrix tag (similar to a QR code) directly from the tool at the presetter and machine. This unique identifier allows specific tool measurement data to be located and loaded directly into a machine’s NC —bypassing the need for embedded RFID chips or costly hardware modifications.

TiD Advantages:

- Cost-Effective – No need for modified tool holders or embedded chips.

- Plug-and-Play – No PLC or ladder modifications required on the CNC machine.

- Wide Compatibility – Works seamlessly with major CNC controllers including FANUC, MAZAK, HEIDENHAIN, SIEMENS, OKUMA and more.

- Cross-machine tool loading – tools can be shared between machine tool platforms with different NCs easily.

- Centralised Data – Maintains a single tool data repository accessible across platforms.

- Intuitive Interface – Graphical configuration tools make setup and operation fast and user-friendly.

TiD is perfect for manufacturers looking to digitise their tool data without overhauling existing infrastructure. It offers a smart bridge between the physical and digital tool environment, while removing the change of erroneous tool measurements ending up in the machines tool table.

As the manufacturing landscape evolves toward full digitisation, NIKKEN’s TP32 and TiD software platforms provide the critical infrastructure needed for high-efficiency operations. From major aerospace suppliers to precision engineering firms, customers across industries are adopting these systems to enhance visibility, cut costs, and stay competitive.