Hot off the Press: NIKKEN eu Shrink-Fit Solution

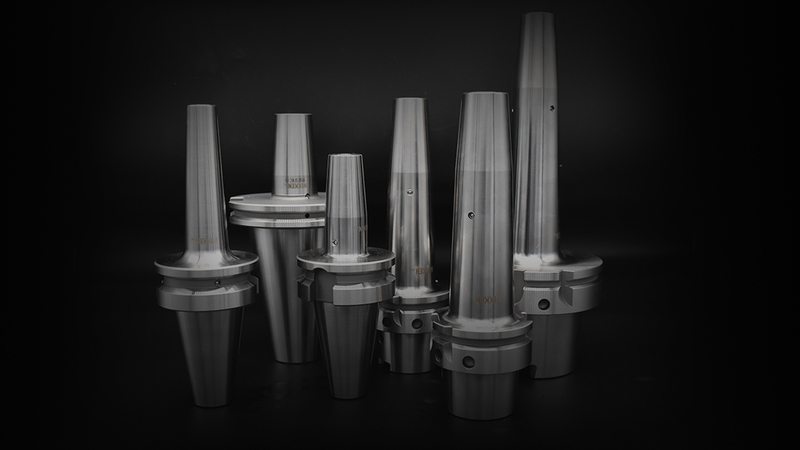

NIKKEN eu are proud to launch the ultimate Shrink-Fit solution. Designed to meet the demands of the most competitive markets, our latest tool holding range has been developed and manufactured using carefully selected materials and processes to suit the majority of machine, tool shank and application requirements.

Based on a ‘mono-block’ body design with a precise bore to grip the cutting tool shank, the range is 100% ground with options available to suit any length, diameter and clearance requirement. We can also supply from stock various options for coolant control to meet the specifics of the respective cutting too.

Our precise manufacturing process allows for a superior tool run-out of less than 0,003 mm, as well as providing a high-quality surface finish and increased speeds. When the body is heated, normally by a magnetic induction coil, the main bore expands to allow the cutting tool to be loaded. Once the process is complete and heat is no longer being applied the holder cools and contracts to accurately grip and retain the shank. In general shrinking can provide greater contact when compared to a standard tool holder or collet system, with the tool shank gripped at 360 degrees for the whole bore length.

LEARN MORE ABOUT OUR RANGE OF SHRINK-FIT SOLUTIONS