An Insight into the Superior Construction of the NIKKEN Worm System

NIKKEN take deep pride in our attention to detail, this is no better demonstrated than at the heart of every NIKKEN Rotary Table, in our patented worm system. 60 years of innovation and technological advancement has been combined to create an unbeatable mechanical solution that offers incredible precision and lifelong durability.

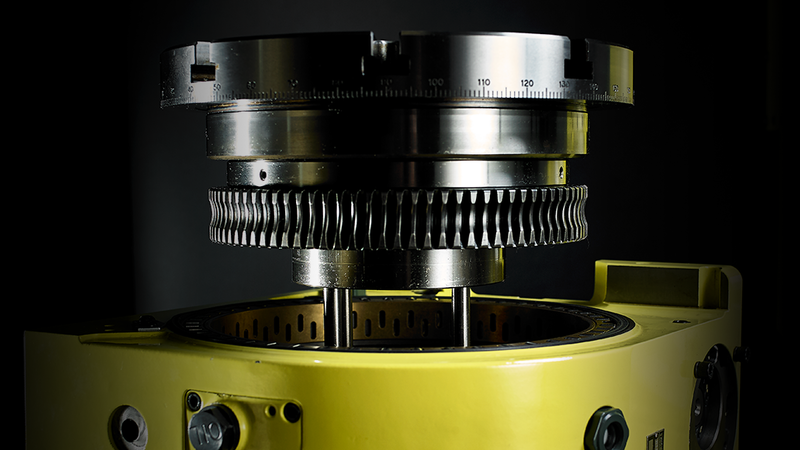

The worm system consists of two critical components which themselves are fundamentally different and unique when compared to anything else in the market today. The worm screw is forged from a combination of special hardened steel and custom-made ground carbide and functions in harmony with our hardened and ground, ion nitride treated, custom steel worm wheel. Both products, once complete, have followed truly unique manufacturing processes and technology to ensure the ultimate quality and reliability NIKKEN are renowned for.

Individually hand-matched and paired together to ensure maximum thread engagement with minimal friction, these techniques and philosophies guarantee that when combined our construction maintains an incredible rotation accuracy whilst also eliminating backlash.

A first in the industry, the design also benefits from a hydrostatic high-pressure oil film to ensure the reliability of the movement. It is this ‘outside the box’ thinking, alongside our carefully selected materials and processes, that eliminates common issues such as backlash between the drive screw and gear negating the typical requirement for regular adjustment of the system to maintain original accuracies.