Linn Products

Glasgow-based Linn Products are famed for supplying some of the world's most advanced premium home audio equipment. With a continual journey towards purity of sound, the aim is to put the listener as close to being in the room with the artist as possible.

With products such as network streaming units, amplifiers, speakers, and the legendary Sondek LP12 record player assembled entirely in-house at their purpose-built, highly automated factory, Linn’s attention to detail is obvious, and the build quality, materials used, and finish of the products reflect the quality of sound they produce.

With a full order book and a desire to offer the best possible aesthetics on products such as the recently launched Klimax DSM network streaming unit, Linn wanted to improve surface finish and decrease manufacturing lead times. Having tried various holders and collets, they wanted solutions which could provide increased stability and better access during machining.

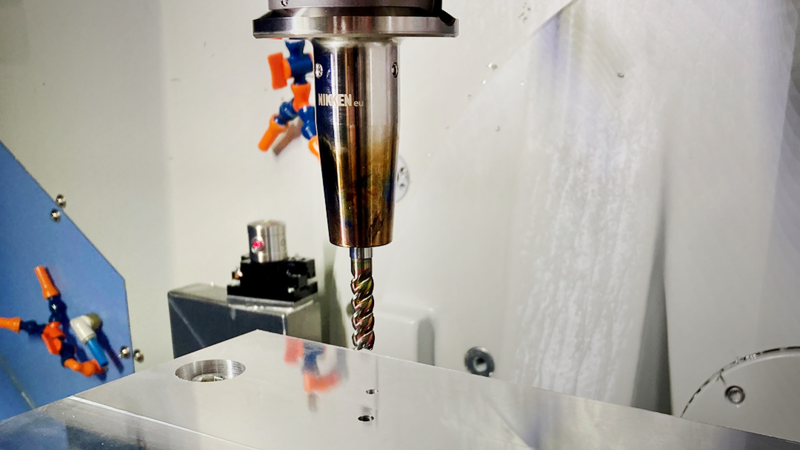

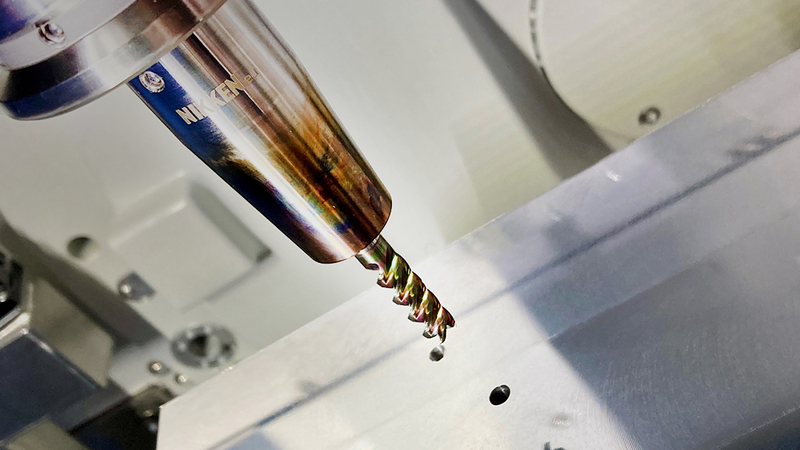

Following heavy investment in automated 5-axis Doosan DVF5000 machining centres, bringing most operations in-house and the ability to run ‘lights out’, Linn were seeking tool holder options that could be instantly available and provide an efficient and stable production process. NIKKEN’s range of Shrink-Fit Holders, Collet Chucks and Face Mill Arbors were top of the company’s list to try.

Having already purchased an Elbo-Controlli NIKKEN E346+ Presetter, Linn were aware of NIKKEN’s superior quality and support. Therefore, investing in NIKKEN’s tooling was a straightforward option with the promised high reliability, rigidity, and absolute accuracy. Since using NIKKEN solutions, Linn Products are delighted with the results, with the Shrink-Fit holders in particular excelling as they enable cutting with high rigidity and accuracy over increased depths, solving a key problem. Alongside the gripping accuracy, the holders also feature face and taper contact on the machine spindles. This added connection stability has brought a huge advantage and allowed the improved surface finishes they demanded to be achieved.

Chris O’Brien, Linn’s Director of Operations, commented: “The relationship with NIKKEN has worked very well, with the products fulfilling their requirements as promised, whilst an excellent arrangement was put in place allowing us to establish an open order and call off holders as we installed machines and programmed different products meaning that we didn’t have to commit to particular sizes and types until we knew what we needed, though the financials had been worked out in advance. This makes life easy for our Manufacturing Engineers and Purchasing staff. Delivery of initial quantities was within a couple of days, and we pay as we go, which is great for cash flow. We are delighted to be working with NIKKEN in this way”.

The beautifully machined Linn Klimax DSM unit can be viewed at https://www.linn.co.uk/uk/network-music-players/klimax-dsm