Ilmor Engineering Ltd

Efficiency rises, and error potential falls as Ilmor choose NIKKEN's TP32 Presetter software.

Northamptonshire-based Engineering consultancy, Ilmor Engineering Ltd, delivers design and manufacturing solutions to high-performance powertrain OEM, Motorsport and Aerospace clients. Established in 1983 by Mario Illien and Paul Morgan, Ilmor has a rich history of becoming one of the market leaders, having provided superior service within their chosen industries for so long.

Ilmor Engineering’s support is helping clients within Formula 1, IndyCar, NASCAR, WEC and WRC maintain competitive advantage whilst providing other customers with more conventional manufacturing-only requirements, including NIKKEN’s very own partner, Boeing.

With an Operations mission to constantly expand capabilities and increase their quality of service, Ilmor Engineering identified a requirement to reduce costs whilst consciously becoming more sustainable within their production process. Having established a strong partnership with NIKKEN dating back 30 years, Ilmor Engineering turned to NIKKEN to find a solution.

Working with their Business Manager, Jack Varley, to review current production processes made up of primarily Matsuura and Mazak milling machines. It was identified that tool setting and tool management would be areas to improve. Current practice was manual tool measurement on a Kelch Tool Setter, followed by manual entry of tool data into each work centre giving potential for error or inaccuracy and manufacture downtime.

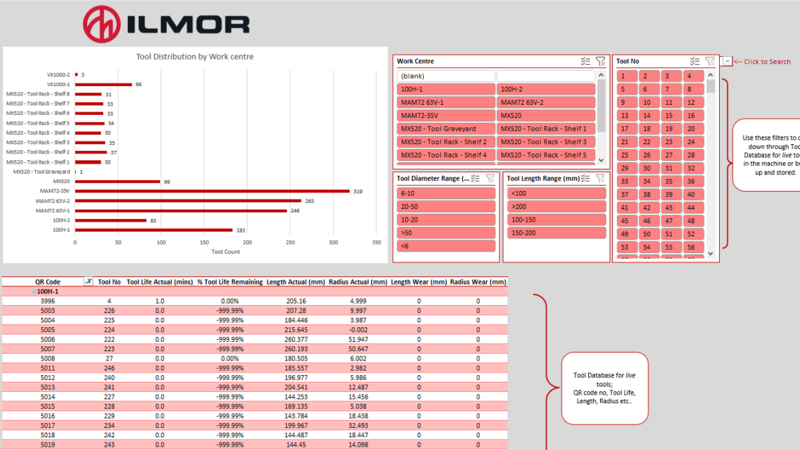

Opting for an Elbo Controlli NIKKEN Tool Presetter & Tool Management System has enabled Ilmor Engineering to tangibly increase manufacture efficiency and productivity, mitigating the potential for tool build errors and allowing tools to be freely changed across work centres reliably to reduce tool inventory.

Prime benefits include a centralised tool database to summarise tool location, current life, life expectancy & history. In addition, the Presetter has given greater confidence when building tools right the first time and automatic transfer of offsets to the work centre. Visual enhancement with the Presetter has allowed Ilmor Engineering to identify worn or damaged tooling in greater detail than before, something which wasn’t possible for Ilmor when using the manual Kelch machine.

This new capability and control, along with NIKKEN’s precision tool holding, is allowing Ilmor Engineering to complete its current portfolio of manufactured parts and components more effectively, including large capacity powertrain parts through to smaller, multi-faced 5 Axis machined products - both in aluminium and steel.

“I cannot fault NIKKEN’s service and support throughout this project; we required a solution that would work across multiple machine architectures, was proven and could be tailored to our needs. NIKKEN matched our expectations.” - Chris Old, Ilmor Engineering Manager.

Discover more about Ilmor Engineering online at https://www.ilmor.co.uk