RD Castings Ltd

Founded in 1976, R D Castings are high precision manufactures of pressure die-castings in both aluminium and zinc alloys, supplying a vast range of both cast and fully machined, finished products to all sectors of industry. Specialising in providing a complete service to their client base, the company offer everything from the concept design to initial solid machining and high-volume manufacturing based at their Mildenhall facility.

Investing in their first NIKKEN table in 2005, R D Castings had previously struggled to provide customers with true 4th axis solutions, opting to move parts from fixture to fixture, resulting in poor output and lower accuracy.

Since installing our first unit we have never looked back nor had any reason to doubt the quality and longevity of these Japanese products. They just work and need little to no maintenance cost spent on them, we only ever undertake a single annual service.

The switch to 4th axis tables required clamping the part just once to provide fully finished components, with an increase in both accuracy and machining time.

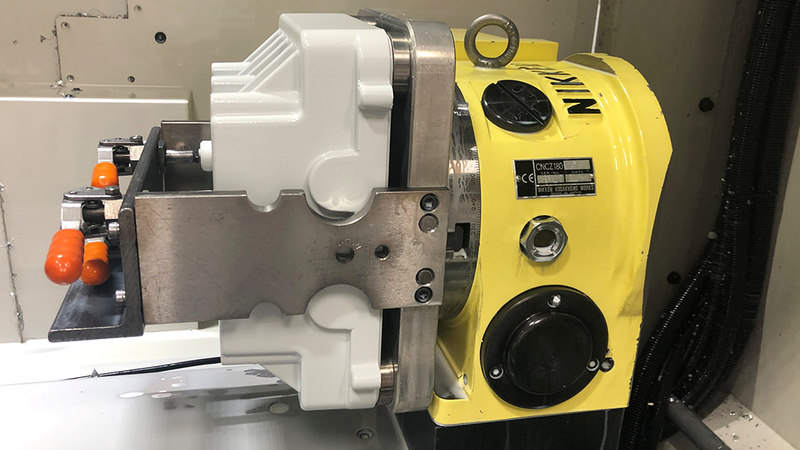

15 years on, R D Castings now own a total of 12 4th Axis CNC180 high speed Rotary Tables, chosen for their wide range of capabilities and versatility. The company utilize them for numerous applications, included manufacturing of HPDC aluminium components and standard face plate work. The team have also combined NIKKEN tables with Saluki sub tables to hold Trunnion fixtures, allowing for maximum accuracy while machining a minimum of 4 faces in one set-up.

A prime example of the long-term performance and durability of NIKKEN products, the original 2005 purchase is regularly employed machining high accuracy gearbox components. Requiring high accuracy, tolerances are often as little as 10-15um, not just on machined features but on angular alignment between faces, which are directly controlled by the NIKKEN CNC180 Tables.

Recently extending their machining facilities to including a dedicated air-conditioned machine shop to operate around twin pallet operations, RD Castings chose to equip all machines with NIKKEN CNC 180 tables providing near-continuous output, citing unmatched precision and high levels of production.

Learn more about our CNC180 solution