Oracle Precision Engineering

South-Yorkshire-based Oracle Precision Engineering was established in 2009 and provides high-quality machining and production. Operating in various sectors, including Oil and Gas, Aerospace, Medical, Marine and more, Oracle has the high-level knowledge necessary to provide a top-quality service. Co-owners Ryan and Shaun set up Oracle to provide affordable, high-quality manufacturing while having fun and enjoying what they do.

With an increasing capacity due to the growing reputation of Oracle, they needed to optimise efficiency, reduce lead times, and save energy. Before using NIKKEN, Oracle could not compete for as many projects as they would liked. With a current set-up which involved measuring each tool within the machines, Oracle identified a need for better accuracy and reliability and ultimately investigated ways to improve their existing process.

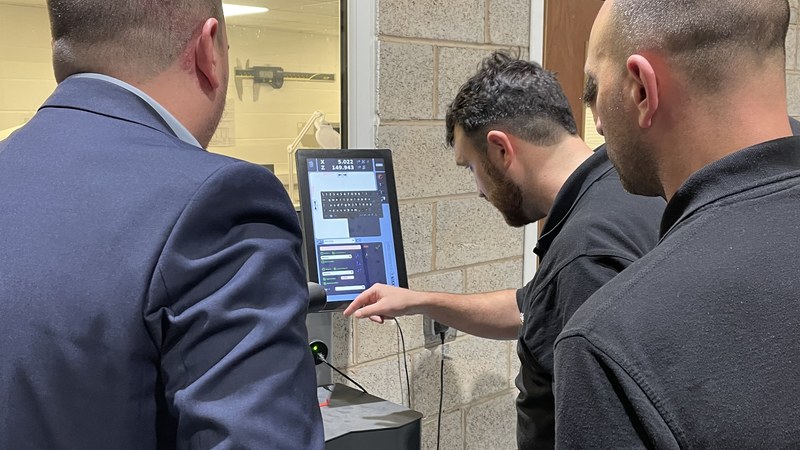

Having developed a strong relationship with UK Sales Manager Lee Rodgers over the past few years, Oracle knew of the superior and high-quality NIKKEN. Lee suggested the Elbo Controlli NIKKEN E346+ Tool Presetting machine due to its absolute accuracy, reliability, and competitive price, providing Oracle with a ‘no-brainer’ solution. Having not used a Presetter before, Oracle required training, which Lee provided at their workshop, demonstrating each step methodically and successfully.

Since using their NIKKEN Presetter, Oracle has been able to ensure maximum run time on their machinery, specifically on their Matsuura’s. The installation also allows Oracle to now measure and check all tool assemblies before loading them into the machine, thus, drastically speeding up tool setting and change over time.

The ultimate benefit is how they have now minimised downtime as a result of the machine spindle running to make parts instead of being static to measure tools - significantly improving efficiency and sustainability whilst focusing their energy consumption on cutting and productivity to reduce overall costs.

Oracle Production Manager, Nathan Lloyd, commented: “The E346+ Elbo-Controlli NIKKEN Presetter is extremely useful to use as shadowgraph checking for tool wear and tool edge radius. We have also found the Presetter to be beneficial for checking boring bar offsets before installation into our sliding head lathe, and as always, have had excellent customer service from NIKKEN. It’s great to deal with the team at NIKKEN and add another quality product to our factory. We thoroughly look forward to working with NIKKEN again very soon.”

Discover more about Oracle engineering here https://www.oracle-precision.co.uk