Gardner Denver

With over 100 years of experience, Gardner Denver is a leading global provider of highly engineered, quality solutions within the transport industry.

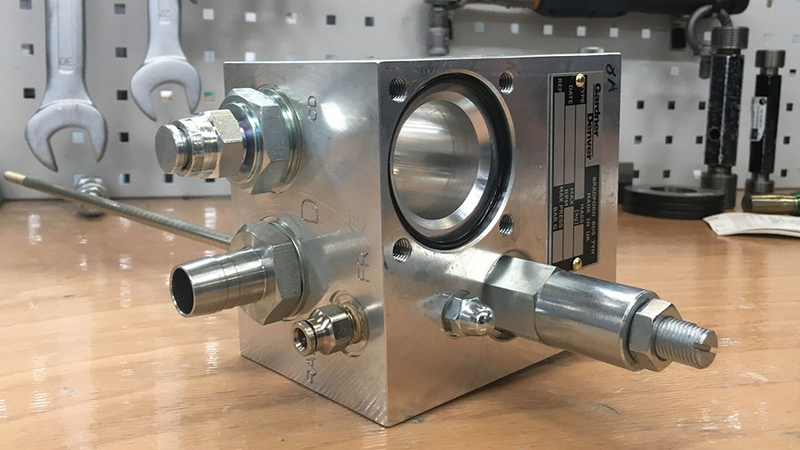

Manufacturing components for compressors, vacuum pumps, blowers and cargo pumps to be used worldwide, time efficiency and quality are critical to the production process. After previously investing in NIKKEN tables for their proven durability and high-performance, Gardner Denver discussed a solution with NIKKEN to decrease manufacturing time on manifold blocks for distribution of hydraulic oil on a Hydraulic Cooler.

With time efficiency being the significant factor, NIKKEN offered a solution using the versatile CNC260 Rotary Table with the portable programmable pendant option, the Alpha 21. This table set up combined with the Modular TRIAG work-holding system and 2 sided trunion plate, enabled the required six-sided machining, as a 2 setup 1 machining operation. The ability to manufacture multiple components without intervention allows for the operator to progress on other assignments, optimizing working hours.

Further flexibility was gained of being able to move the full setup between machining centres, due to the design and the Alpha21 table combination, should production capacity demands require it.

Having previously used components contracted from sub-contractors, the new Nikken/TRIAG modular solution also allowed for all components to be manufactured within the UK, guaranteeing quality while eliminating wait times.