4th Axis Solution see's Business Opportunities Soar for Automotive Manufacturer

A leading aftermarket parts supplier for car and motorcycle enthusiasts recently contacted NIKKEN for a time-saving solution, which would free up time for more intricate projects.

Finding themselves spending unnecessary time manually moving each component 90 degrees to achieve 4 sided machining which would result in the initial position being lost, the machine tripping or turning the part into scrap material, they turned to NIKKEN to find a solution.

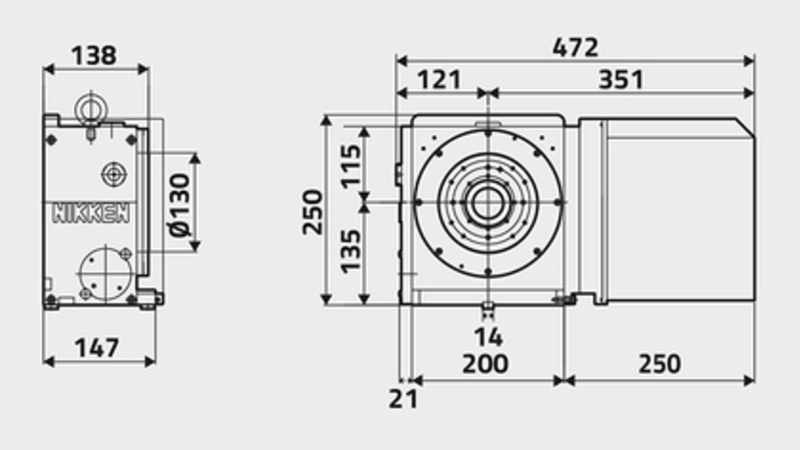

Working with their local Business Manager, the solution proposed consisted of a NIKKEN 4th Axis Rotary Table, the NCT200 complete with a Trunnion Set Up allowing them to manufacture more complex parts in fewer operations, opening the business up for more intricate projects as originally requested whilst reducing machine downtime and scrap.

The NIKKEN NCT200 is a compact rotary table offering an exceptional clamping torque of 900Nm and a 25% increase in rigidity which was one of the major selling points to our customer.

When I looked at what the competitor was offering in terms of driving torque, I thought I’d done a miscalculation as NIKKEN offered double the clamping force.

The company have also noticed a considerable increase in productivity as they can now write more extended programmes, freeing up operator time to work on other projects.