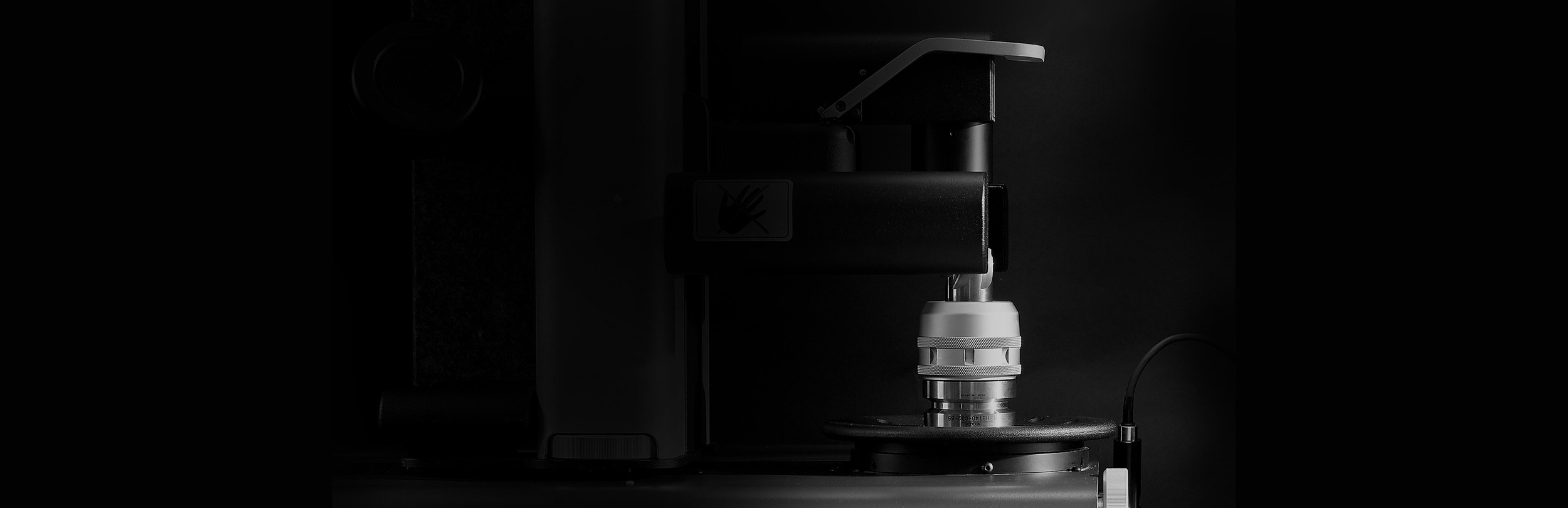

The Hathor SIX Tool Presetting machine is designed completely free-standing on its own integral base; Hathor SIX features ground granite and stainless steel construction combined with a large digital camera and touch screen menu system – these new electronics provide operational and functional simplicity that is second to none.

Featuring a new electronic control: a powerful fanless PC with Linux operating system for the integrated management of the functions of measurement / inspection tools, machine origins and toolsets. Ease of use thanks to the integrated touch screen.

-

The precision Spindle System is fully interchangeable and utilises a one piece cartridge - eliminating the need for adaptors and the errors associated with their use.

-

Working via your DNC system, TdSIX converts measured tool data into CNC code for direct loading into the machine controller and associated tool offset pages.

-

A large digital camera combined with a touch screen menu system – these new electronics provide operational and functional simplicity that is second to none.

Spindle System

Featuring a Spindle System that is fully interchangeable and utilises a one-piece cartridge - eliminating the need for adaptors and the errors associated with their use. Incorporated within the spindle is our innovative universal mechanical clamping system with electronic tool clamping confirmation (also now available as an option to suit HSK tool shanks).

Software Package

Also included with our Hathor SIX model is our TdSIX software package. Working via your DNC system, TdSIX converts measured tool data into CNC code for direct loading into the machine controller and associated tool offset pages.

Hathor Six Brochure

(PDF - 1.49 MB)

Hathor SIX Tool Presetter

(PDF - 197 KB)

TECHNICAL DATA

Measuring range: Diameter max 400 mm (radius 200 mm); height max 600 mm.

Standard mechanical/electronic and optical equipment:

- Base and column made of natural granite to guarantee the maximum accuracy: linearity max error 2 μm/Mt – certification with Taylor Hobson res.1 μm/Mt. electronic millesimal level. ELBO CONTROLLI NIKKEN Linear Transducers in optical glass type AS 371 certified HP laser: Axes resolution: X= 1 μm, Z= 1 μm.

- Machine structure in stainless steel offering high mechanical strength and long life, floor mounted with self-levelling supports in non-deformable steel.

- ISO / BT / HSK / VDI... etc. Interchangeable rotating spindle-holder (to be specified) max run-out error < 2 μm. Spindle Index in four angular positions: 0°-90°-180°-270°.

- Linear slideways: 2 for X axis slideways and 1 for Z axis slideway.

- Double re-circulating ball bearing slides (four in total), lubricated for life. Universal electro-mechanical tool clamping (ISO only).

- Pneumatic-mechanic braking of the spindle-holder rotation.

- Constant load Archimedean spiral spring (as opposed to a mass counter-balance system).

Vision-system for tool measuring and cutting inspection consisting of:

- C-MOS sensor – Framed image area 6,4 x 6,4 mm.

- Magnification around 30X.

- Bi-telecentric lens.

- Doublet lenses at low F/Number in order to eliminate the error of the clearness circle.

- Red light episcopic LED’s illuminator with ring lens, red light diascopic LED puntiform illuminator.

Machine operator interface through:

- TFT 15” colour Touch Screen.

- Intel Atom D.C. fanless motherboard.

- UBUNTU LINUX operating system.

- Data storage on solid state disk SSD.

- X and Z axes lock management for a translation speed lower than 2 mm/sec.

Standard software:

- Operator-machine interface simple and intuitive by single screen function.

- Ease of use thanks to the integrated touchscreen.

- CNC machine origin and spindle adaptor management.

- Tool list creation and/or single tool.

- Automatic change of CNC machine origin allocation. T

- ool set and Post Processor universal generator. Printable tool set report.

- Theoretical measurements and tolerances management.

- Anti-dust cover provided for when not in use.

Overall dimensions: Length = 1240 mm, Height = 1840 mm, Depth = 558 mm. Net weight: 185 Kg.

| Hathor SIX | |

|---|---|

| X Axis Measure (Diameter) | 400 |

| Z Axis Measure (Length) | 600 |

| Natural Granite Base & Column | ✓ |

| Interchangeable Spindle Cartridge | ✓ |

| C Axis Display Spindle Body and Spindle Cartridge | ✗ |

| Interchangeable Spindle Max. Run-Out Error | 2µm |

| Automatic Rotation of the Spindle | ✗ |

| Spindle Index in four Angular Positions (0º, -90º, -180º, -270º) | ✓ |

| Spindle Rotation Brake | Pneumatic |

| Spindle Identification System (NFC recognition) | ✗ |

| Clamping System | Manual / Mechanical |

| Tool Inspection Function/Capability | ✓ |

| Elbo Controlli NIKKEN Triple Camera System (Cutting Edge Inspection) | ✗ |

| Main Camera System Resolution | 1µm |

| Main Camera System Measuring Range (C-MOS Sensor Framed Image Area) | 6.4mm x 6.4mm |

| Secondary 'Twin' Camera System Measuring Ranges (Framed Image Area) | ✗ |

| Main Camera Magnification | 30X |

| Secondary 'Twin' Camera System Magnifications | ✗ |

| Elbo Controlli NIKKEN Certified Optical Scale Axes Resolution | 1µm |

| Elbo Controlli NIKKEN GS371 Certified 'Natural Granite' Optical Scale Axes Resolution | ✗ |

| Touch Screen System (Operator Interface) | TFT 15" |

| Keyboard and Mouse | ✗ |

| Electronics/Processor | Intel Atom Fanless Motherboard |

| Firmware/Operating System | Ubuntu Linux |

| Data Storage | SSD |

| Elbo Controlli NIKKEN Tool Management Software | TdSIX |

| Tool Set Management and Post Processor Universal Generation | ✓ |

| DXF File Import and Creation | ✗ |

| Balluff Read/Write Ready (Balluff Hardware Required)? | ✓ |

| Elbo Controlli NIKKEN TiD Ready? | ✓ |

| Elbo Controlli NIKKEN TP32 Ready? | ✓ |

| Elbo Controlli NIKKEN IS 'Integrated Solution' with Twin Screen and Dual OS Option Ready? | ✗ |